IRI Announces Winner of Prestigious Holland Award

Should manufacturers strive to be “cutting edge”?

That’s the question explored in “Is ‘Cutting-Edge’ Good? Assessing Product Newness Factors in Technologically Turbulent Environments,” the paper that won the Innovation Research Interchange’s 2023 Maurice Holland Award.

- The honor, named for the IRI’s founder, has been bestowed annually since 1982 by the IRI, the NAM’s innovation division. It goes to the best article published in the IRI’s flagship publication, Research-Technology Management.

- Winning papers exemplify a commitment to significant work in research and development and innovation management, originality of new management concepts and excellence in presentation.

- This year’s paper, by Michael Obal, Todd Morgan and Wesley Friske, does all three, according to the IRI.

Providing value: “In innovation, novelty generates the most attention but does not always translate into better value for the company and customers,” said Research-Technology Management Editor-in-Chief Yat Ming Ooi.

- “This article tells readers when and to whom novel new products matter and why companies need to strike the right balance to ensure better new product performance.”

Authors respond: Research-Technology Management “is a leading academic journal for innovation-related research, and thus having an opportunity to publish an article in RTM is a significant accomplishment in its own right,” said co-author Friske, an associate professor at Missouri State University’s marketing department. “I am also grateful for the opportunity to share this award with my friends and co-authors, and it is particularly important to me now that Todd is no longer with us.”

- Co-author Morgan, an assistant professor at Cleveland State University’s Monte Ahuja College of Business, passed away in 2023.

- “I’m honored to receive the Holland Award from Research-Technology Management alongside Todd and Wes,” said co-author Obal, an associate professor at the University of Massachusetts Lowell’s Manning School of Business. “All three of us have aimed to publish academic work that impacts practitioners throughout our careers, [so] receiving an award from a journal that specifically focuses on bridging the gap between academia and practice is especially gratifying.”

- “This paper and award are bittersweet as Todd is no longer with us,” Obal continued. “[But] I am encouraged that his work will continue to have an impact.”

About the IRI: The IRI offers insights, case studies, research, benchmarks and strategic connections—all built around a set of innovation growth drivers as determined by members annually. Click here to learn more about the IRI.

U.S. and European Union Strengthen Transatlantic Trade Ties

The sixth ministerial of the United States–European Union Trade and Technology Council, held in Leuven, Belgium, emphasized the deepening cooperation between the U.S. and the EU in navigating global economic pressures and technological advancements.

What’s going on: Secretary of State Antony Blinken, joined by Secretary of Commerce Gina Raimondo and U.S. Trade Representative Katherine Tai, joined European Commission leaders in a discussion that centered on fostering economic security, the importance of AI governance, cooperation on secure supply chains and a transatlantic commitment to reducing reliance on high-risk suppliers.

- This collaboration, Secretary Blinken said in remarks to the press at the council’s outset, proved that there has been “increasing alignment” between the United States and the European Union on these and other issues in recent years.

- “Together, we represent almost half of world GDP, and that means that there’s a certain weight that comes with having a shared position on something,” Secretary Blinken said. “And whether that’s dealing with China or any other challenge, it makes a big difference.”

Growing collaboration in AI: The meeting additionally underscored unwavering support for Ukraine from the U.S. and the EU amid geopolitical challenges, as well as a commitment to driving innovation and security in technology and trade.

- One tangible outcome of the TTC was an update of the “Terminology and Taxonomy for Artificial Intelligence” (i.e., of the definitions of key terms used by the EU and U.S. when discussing AI). This underpins the workstream of the TTC to “ensure the safe, secure and trustworthy development and use of AI,” according to the U.S.–EU joint statement.

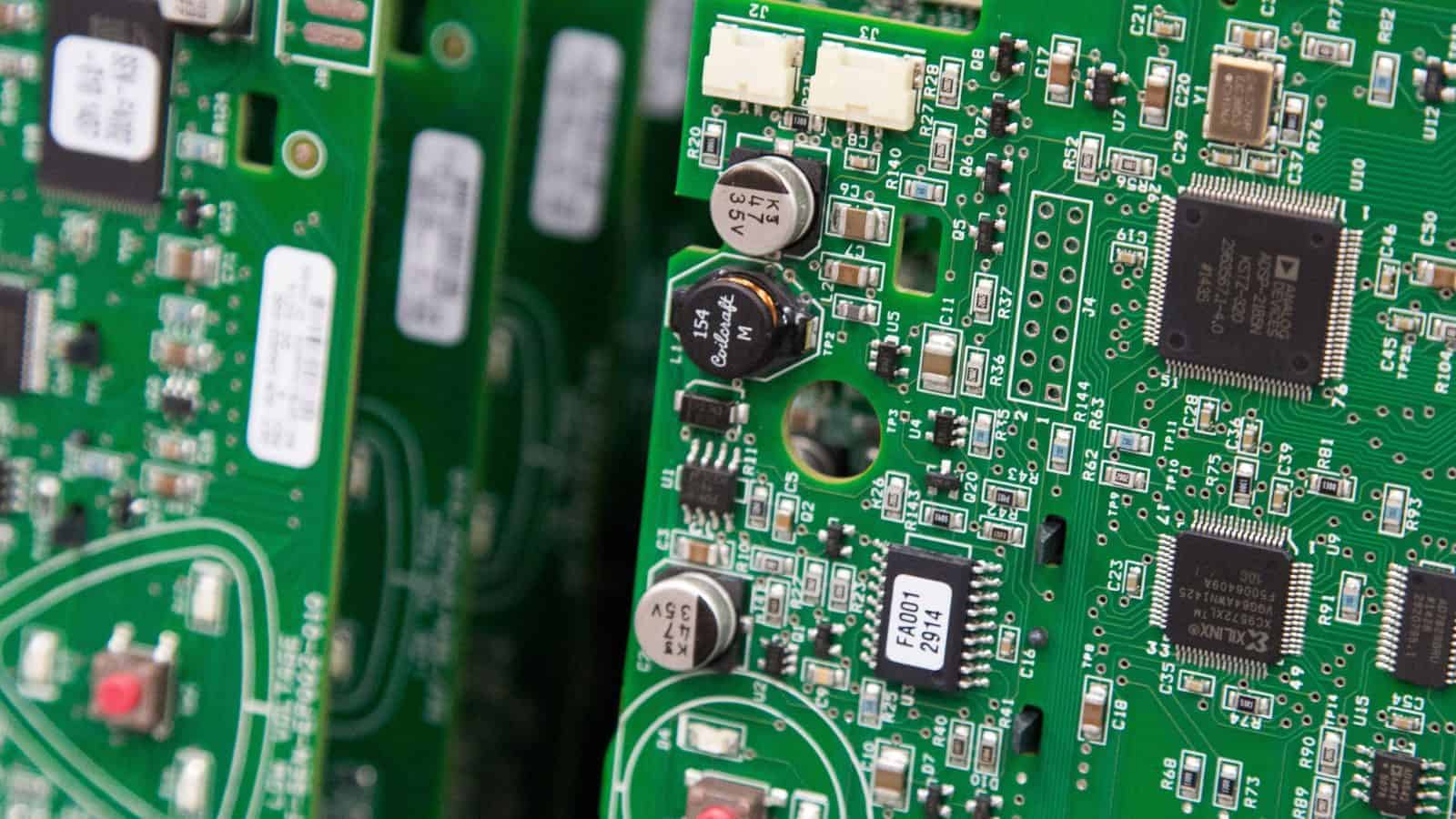

Shared concerns about Chinese semiconductors: Competition from heavily subsidized chips produced in China was a key focus at the ministerial, particularly in light of the anticipated ramping up of “legacy chips” manufactured in China over the next few years. The Chinese government’s significant financial subsidization of the chip-producing sector, Secretary Raimondo warned, could lead to considerable market imbalances between China and the U.S. and EU.

- Both the U.S. and EU pledged to continue working together to address destabilizing Chinese exports of semiconductors in the coming years, including to collect and share nonconfidential information and market intelligence about nonmarket policies and practices, to consult each other on planned actions and to potentially develop joint or cooperative measures to address distortionary effects on the global supply chain for legacy semiconductors.

TSMC to Receive Up to $6.6 Billion in CHIPS Funding

The Biden administration on Monday announced that TSMC’s Arizona subsidiary will receive up to $6.6 billion in grants from the 2022 CHIPS and Science Act, The New York Times reports. The announcement is the latest move by the Biden administration to make the United States a leading producer of cutting-edge semiconductor technology.

What’s going on: The funding “will help support the construction of TSMC’s first major U.S. hub, in Phoenix. The company has already committed to building two plants at the site and will use some of the grant money to build a third factory in Phoenix, U.S. officials said on Sunday.”

- The company will “increase its total investments in the United States to more than $65 billion, up from $40 billion.”

- “TSMC’s investment is expected to create about 6,000 direct manufacturing jobs and more than 20,000 construction jobs, federal officials said.”

- In addition to the grants, the federal government is also offering TSMC up to $5 billion in loans.

Impact on U.S. chip production: “With projects such as TSMC’s, the U.S. is on track to make about 20% of the world’s cutting-edge chips by 2030, the Commerce Department said. It called the project the largest foreign direct investment in a new project in U.S. history,” reports The Wall Street Journal (subscription).

- Earlier this year, the Biden administration announced major chips funding awards for Intel and GlobalFoundries.

The NAM’s reaction: “Today’s announcement from TSMC and @CommerceGov makes America stronger,” the NAM wrote in a social post Monday. “The NAM-championed CHIPS and Science Act continues to spur new investments in cutting-edge semiconductor technology that is essential to advancing U.S. economic competitiveness.”

MLC Announces Manufacturing Leadership Award Finalists

The Manufacturing Leadership Council, the NAM’s digital transformation division, has announced the 2024 Manufacturing Leadership Awards finalists.

About the awards: Now in their 20th season, the Manufacturing Leadership Awards

honor the most outstanding manufacturing companies and their leaders for groundbreaking use of advanced manufacturing technology.

- This year’s program features nine project categories, including Artificial Intelligence and Machine Learning, Digital Supply Chains and Sustainability and the Circular Economy.

- It also includes two categories for individuals: Digital Transformation Leadership for executive-level manufacturing leaders and Next-Generation Leadership for up-and-coming leaders age 30 and under.

How we decide: Nominations are judged by an outside panel of digital manufacturing experts with deep industry knowledge and experience.

- For project entries, judges assess an initiative’s effect on improving manufacturing processes, furthering business goals and advancing company strategy, as well as how much digital technology the project used.

- For individual nominations, judges look at each person’s impact both inside and outside their organization, and whether they meet the criteria as a role model for other manufacturing leaders.

Celebration and ceremony: Winners for both of these categories will be announced at the Manufacturing Leadership Awards Gala on June 5 at the JW Marriott Marco Island Beach Resort.

- Award finalists will also be recognized, as will winners of the Manufacturing in 2030 Award, the Manufacturing Leader of the Year, the Small/Medium Enterprise Manufacturer of the Year and the Large Enterprise Manufacturer of the Year.

- The gala caps off Rethink, the industry’s leading event for accelerating digital transformation. (Rethink also takes place in Marco Island, June 2–5.)

The last word: “More than ever, manufacturers are finding that digital technology investment is good for business as they achieve new levels of performance in efficiency, productivity and innovation,” said MLC Founder, Vice President and Executive Director David R. Brousell.

- “The finalists we are recognizing for this year’s awards have demonstrated not just the business benefit of Manufacturing 4.0 technology, but also a fresh and imaginative approach to applying it in a transformative way.”

Honda Winds Up a One-of-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

Honda Winds Up a One-of-a-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind-tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

Innovation First: How Oshkosh Corp.’s 107 Years of Experience Deliver Innovative Solutions

Oshkosh Corp. manufactures a wide array of purpose-built vehicles and equipment, but at its heart, it’s an industrial technology company focused on engineering, President and CEO John Pfeifer told the NAM recently.

“If you look at us up close, we’re really an engineering company,” Pfeifer said. “If you look at a fire truck up close, you’d be amazed at the amount of design engineering [that goes into] to this machine.”

A fire truck boom: Fire trucks are indeed a big part of business at the 107-year-old company, headquartered in its namesake Oshkosh, Wisconsin. In fact, there’s such a demand for the vehicles—which Oshkosh offers in more than 300 different shades of red—from municipalities throughout the U.S., the firm has a two-and-a-half-year backlog.

- The major reason: rising home values. Counties and towns get their revenue from property tax receipts. When those are strong, as they have been in recent years, the governments can afford to upgrade their fleets—which they’re now doing in earnest, Pfeifer said.

Innovation = safety + productivity: They’re going to Oshkosh for the very reason Pfeifer considers the company first and foremost an engineering outfit. In addition to fire and other municipal and vocational trucks, the company manufactures defense, construction and aviation ground support equipment.

- “We’re able to accelerate innovation because of our technical capabilities as a company,” he explained. “We’re able to electrify things that are not supposed to be electrical—like a 40,000-pound municipal fire truck.”

- Worldwide, Oshkosh employs a team of between 1,600 and 1,700 engineers just for design work, according to Pfeifer.

- In any product it makes, Oshkosh’s primary concern is improving the safety and productivity of “the everyday heroes who do the hardest work. Military, firefighters, mail carriers—those are the people who use our products, and that’s why innovation matters. Our products allow them to be more productive and a lot safer.”

Legislation-supported growth: But it’s not just those vehicles that are seeing exploding demand from customers.

- Historic federal investments, such as those in the CHIPS and Science Act and the Bipartisan Infrastructure Law and the Inflation Reduction Act, “have spawned huge infrastructure projects,” Pfeifer added. “So it doesn’t matter what you’re producing; you can’t produce it without our equipment.”

- Last year, contractors in North America kicked off approximately $350 billion worth of projects, with electric vehicle and semiconductor facilities and data centers all acting as drivers of that growth.

Speaking of EVs: Oshkosh has a lot to boast about in the EV space.

- It was recently chosen by the U.S. Postal Service to design the agency’s Next Generation Delivery Vehicle, a mail van “customized specifically for the needs of mail carriers,” according to the Oshkosh website. The vehicle’s propulsion platform can accommodate both traditional internal-combustion and battery-electric engines.

- And in addition to having developed a lithium-ion battery-powered refuse and recycling vehicle, Oshkosh also manufactured the first electric fire truck in service in North America. It’s the Pierce® Volterra™ Pumper, and the Madison Fire Department’s fleet in Madison, Wisconsin, has a purchase order agreement for it following a highly successful 18-month placement of one of the Pumpers.

Coming up: What’s next for Oshkosh? With its healthy balance sheet, the company is investing for the long haul, Pfeifer told the NAM.

- “We’re hiring a lot and opening new facilities,” Pfeifer continued, adding that Oshkosh subsidiary JLG Industries Inc.—which makes the popular SkyTrak® telehandler hydraulic lift machine—is expanding its 500,000-square-foot manufacturing facility in Jefferson City, Tennessee, and Oshkosh recently opened new plants in Spartanburg, South Carolina, and Murfreesboro, Tennessee.

The last word: The firm is also focusing on strategic acquisition work, Pfeifer said.

- Last year, it purchased AeroTech, a company that makes cargo loaders and other airport ground support equipment.

- “We’re very patient, but when we see the opportunity to acquire a business and enter a new product category or adjacent market where we can make a difference, we do it.”

An Engineer Looks to the Future at ExxonMobil

It was an internship in modern manufacturing that changed Bobi Simonsen’s view of the industry—and gave her a sense of how many different kinds of opportunities were available.

“I remember school projects where I would just picture an engineer with a hard hat doing calculations,” said Simonsen. “I didn’t realize how much creativity and collaboration is involved in engineering. There is way more complexity than I had ever realized.”

A new path: Shortly after that internship, Simonsen got connected with ExxonMobil through the University of Texas—and she hasn’t looked back since.

- Today, she’s a technical supervisor at the largest polyethylene site in the world, leading teams of engineers, chemists and technicians who perform experimental commercial-scale trials and improvement projects on the tough synthetic resin used in bags, containers and other packaging.

A sense of purpose: Simonsen is particularly interested in opportunities to support sustainability and sees manufacturing as the perfect place to make an impact.

- “I know young people are really passionate about sustainability, making a difference and having a purpose, and all of those are things you can do in manufacturing, especially at a place like ExxonMobil,” said Simonsen. “We are global, we are integrated and we have the resources and scale to impact an entire industry. That’s the reason I came to work here.”

A push for parity: Simonsen also sees how the lack of women in science, technology, engineering and math feeds into a shortage of women in manufacturing, and she’s eager to see more young women find their way into the field.

- That’s why she leads industry meet-and-greet events on behalf of ExxonMobil at the University of Texas, volunteers at “Introduce a Girl to Engineering Day” events for K-12 students in Austin and Houston and hosts lunch-and-learn sessions with UT’s Society of Women Engineers and the American Institute of Chemical Engineers.

- She also leads ExxonMobil’s SWE conference team, who recruit, share sessions and lead “Invent It Build It” outreach activities through SWE.

- “We do a good job of recruiting candidates who reflect the diversity of the pipeline; my classes in college were 30% women, and that’s translating to the same 30% who make their way into ExxonMobil manufacturing,” said Simonsen. “But that’s not 50%, which is why it’s vital to engage women and minorities to get interested in STEM so we can bring them into classes and then the workforce as they graduate.”

New visibility: Recently, Simonsen was named an Emerging Leader in Manufacturing by the 2024 Women MAKE Awards, a distinction for a select few women under the age of 30 who have achieved rare accomplishments at the start of their careers in manufacturing.

Advice for women: While most workers in the industry are still men, Simonsen encourages women to consider the broad range of opportunities available in manufacturing.

- “I would say, ‘Try it,’” said Simonsen. “Consider trying it, even for a short period like an internship. Because if you step in, and you like it, you can find yourself working on the biggest challenges in the world.”

U.S. Awards Intel Largest Chips Grant

The U.S. will award Intel up to $8.5 billion in grants and as much as $11 billion in loans to expand chipmaking capacity and capabilities in four states, The Wall Street Journal (subscription) reports.

What’s going on: The funds, set aside under the NAM-backed 2022 CHIPS and Science Act to bolster domestic semiconductor production, “will go toward new factories and expansion projects in Arizona, New Mexico, Ohio and Oregon, the Commerce Department said.”

- Spurred by the federal funding, “Intel’s total investment in U.S. projects in the next five years is expected to exceed $100 billion,” according to the Journal, and to create more than 10,000 manufacturing jobs and about 20,000 construction jobs, according to the Commerce Department.

Largest award: The grant to Intel, the largest American chipmaker by revenue, is also the largest CHIPS Act award. It follows a February announcement of a $1.5 billion award to GlobalFoundries Inc.

- The award will support the reshoring of production of leading-edge logic chips, which are “essential to the world’s most advanced technologies like artificial intelligence,” the Commerce Department said.

- President Biden was in Chandler, Arizona, Wednesday to visit Intel’s Ocotillo chip-manufacturing campus.

Why it’s important: “We can’t just design chips; we have to make them in America,” Commerce Secretary Gina Raimondo told reporters on Tuesday, the Journal reports. “It’s an economic security problem. It’s a national security problem. And we’re going to change that.”

How it will work: The funding will be doled out in stages, “according to construction and manufacturing milestones,” the Journal said.

- “In Chandler, Arizona, the money will help to build two new chip plants and modernize an existing one,” CBS News reports. “The funding will establish two advanced plants in New Albany, Ohio, [and] … [t]he company will also turn two of its plants in Rio Rancho, New Mexico, into advanced packaging facilities. And Intel will also modernize facilities in Hillsboro, Oregon.”

The NAM weighs in: Wednesday’s “record, multibillion-dollar award is great news for [Intel] and U.S. manufacturing competitiveness,” the NAM wrote in a social post. “The NAM was a vocal supporter of the CHIPS and Science Act, and we will continue to champion policies that support the expansion of chip production in America.”

Trend of the Week: Smart Factories

In 2024, factories will just keep getting smarter. From product design to supply chain management, the sophistication of Manufacturing 4.0 (the current wave of technological evolution) will keep on growing. Here’s what manufacturers should know about these advances and how the NAM can help.

What manufacturers should do: Manufacturers looking to make their factories smarter are focusing on four key strategies:

- Creating efficiencies to improve the bottom line with automation and other M4.0 technologies

- Leveraging smart factories to overcome challenges, such as the workforce crisis and supply disruptions

- Ensuring connectivity on the factory floor to allow for use of plant data to create new business models and revenue streams

- Using M4.0 technologies to improve quality control, speed time to market, enhance safety, boost profits, contribute to sustainability goals and engage employees

Expert opinion: Companies are increasingly investing in industrial connectivity, according to PTC Vice President of Market Development of IoT James Zhang.

- “Rather than approaching industrial connectivity with point-to-point integrations, companies are developing holistic, enterprise-wide strategies,” he explained.

- “This approach streamlines and standardizes data from heterogenous manufacturing environments to a single industrial connectivity platform to provide secure, reliable data for OT systems, including MES and SCADA, and IT systems, including data analytics and industrial IoT.”

Resources for you: Check out these NAM resources that will help guide you through these technological changes:

- The Manufacturing Leadership Council, the NAM’s digital transformation division, offers extensive advice and expertise on Manufacturing 4.0 technologies and how to use them.

- NAM Cyber Cover can help you protect your smart factories, as the increase in digitization also opens new avenues for cyber criminals.

- Check out this podcast from the Innovation Research Interchange (the NAM’s innovation division), which covers current research into the adoption of cutting-edge technologies.

Read the full 2024 trends report here.