NAM Election Playbook: Synergies, Not Sides

The NAM isn’t playing favorites in an election year. Instead, it’s redoubling its post-partisan approach to advocacy. NAM President and CEO Jay Timmons’ message to manufacturers: the association will leverage its hard-won, bipartisan influence to advance manufacturers’ priorities, no matter who’s in charge.

- “That’s what we’re about. Policy that helps people. Policy—not politics, personality or process. That’s what will guide us in 2024 and beyond,” Timmons said in a speech that helped kick off the NAM board meeting this week, before more than 200 of manufacturing’s leading executives in Phoenix, Arizona.

Why it’s important: “Both sides want us on their side,” Timmons emphasized while recounting a recent legislative debate. That trust and respect, he said, translates into wins: agencies modifying rules to avoid lawsuits and high-level White House officials acknowledging the impact of NAM campaigns.

Battles loom: But the very system enabling these victories is under threat, Timmons warned, placing the onus on manufacturers to not just build products, but to empower the NAM to utilize their voices and stories to advance policies that strengthen the economy and underpin democracy and free enterprise.

- Tax showdown: Any new taxes on manufacturers are a nonstarter, Timmons vowed, staking a claim in the looming 2025 tax fight and reiterating manufacturers’ call for immediate passage in the Senate of full capital expensing, R&D expensing and interest deductibility.

- Regulatory onslaught: From new Environmental Protection Agency air standards to the broader regulatory agenda, Timmons argued that overzealous rules impede manufacturing competitiveness. He specifically criticized the new PM2.5 standards, saying the EPA “set them at a level that is lower than the EU or the UK, and imposed a compliance timeline that is far more aggressive.”

- LNG halt: Timmons blasted the Biden administration’s liquefied natural gas export permit freeze, calling it shortsighted and detrimental to both manufacturers and broader U.S. energy and climate goals. “They want to address climate change?” he asked. “So they’re going to have other countries buying and burning dirtier energy? They want to support our allies around the world? So they’re going to force Europe and Japan and others to get their fuel from the likes of Russia?”

- Immigration deadlock: He criticized inaction on both sides of the aisle, saying border security and workforce solutions can—and must—coexist.

Opportunity ahead: Despite considerable challenges, Timmons sees an opportunity for manufacturers to take the lead in promoting American values and sound policies that fuel the industry’s strength.

- “This election year, manufacturers can help renew a shared sense of purpose,” Timmons told executives. “Remind Americans why our country—our system rooted in God-given human rights and fundamental freedom—is worth celebrating and defending.” At stake is not just the next regulatory win, but the very system that made U.S. manufacturing a global powerhouse, he said.

- America’s bicentennial celebration helped us see beyond the divisions of the day, Timmons observed. As we approach the 250th anniversary of the signing of the Declaration of Independence, “it’s manufacturers who are positioned to cultivate that patriotic spirit,” Timmons said. It’s more than just bottom lines. “We can help mend the divides—so that we can promote policy that will strengthen manufacturing in America.”

Arizona: Manufacturing’s Crossroads

In the heat of Arizona’s “Silicon Desert” and surrounding communities, the future of America’s global competitiveness and climate goals aren’t just being forged—they also hang in the balance.

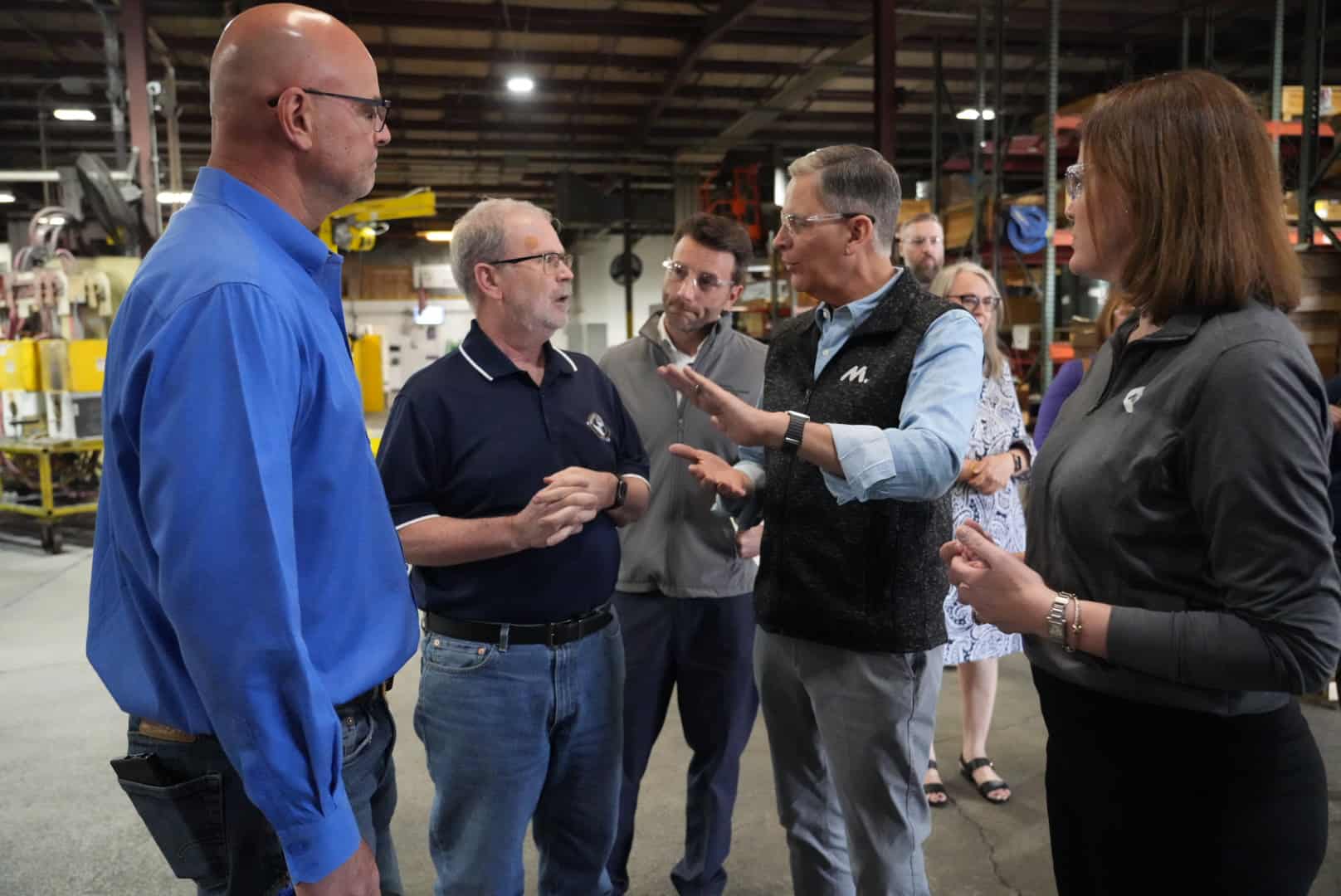

Last week for the first time in 2024, the NAM brought its Competing to Win Tour to Arizona, and that stark contrast between the status quo and the probable future was on display in Phoenix at global semiconductor equipment manufacturer Benchmark and small manufacturer Valley Forge & Bolt and at Resolution Copper in Superior.

- NAM President and CEO Jay Timmons, Manufacturing Institute President and Executive Director Carolyn Lee—who leads the NAM’s 501(c)3 workforce development and education affiliate—and Arizona Chamber of Commerce & Industry President and CEO Danny Seiden met with local manufacturers to gain their perspective and insights.

Why it matters: The Biden administration and Congress have secured key measures to bolster manufacturing in the U.S., including the NAM-championed CHIPS and Science Act and tax credits in the Inflation Reduction Act to manufacturers investing in advanced production and energy projects. But raw material, workforce and tax and regulatory policy challenges threaten to undermine policy aspirations.

Silicon Desert expansion: With the CHIPS and Science Act poised to transform the sector, Benchmark President and CEO Jeff Benck and Executive Vice President and Chief Operating Officer Dave Valkanoff led the tour of their state-of-the-art Phoenix facility.

- In a good spot: Benchmark is well-positioned for the coming growth in semiconductor equipment demand. It is focused on securing its workforce and navigating a complex regulatory landscape to maximize the opportunity.

- Workforce woes: Even with the NAM and the MI’s Benchmark-supported Creators Wanted campaign boosting the industry’s image and the MI’s FAME initiative training thousands of technicians, finding skilled labor remains the top challenge. Benchmark advances earn-and-learn programs and partnerships with Arizona State University and community colleges to help fill the pipeline, actions that, according to Lee, “can help change the game.”

- Red tape delays: Regulatory hurdles pose obstacles. Benchmark seeks streamlined permitting and sensible rules to maintain their global edge.

- Bullish outlook: Benck is optimistic about the future of U.S. manufacturing and semiconductor demand. Investments in people and technology position the company well to deliver the next generation of innovation.

Taxes and immigration: The NAM’s return visit to Valley Forge & Bolt, after a stop last year with Sen. Kyrsten Sinema (I-AZ), shone a spotlight on the real-world impact of stalled tax policy and the urgent need for reform.

- Valley Forge & Bolt saw record sales in 2023 thanks to 2017 tax reforms boosting its equipment upgrades. Now, with provisions like full capital investment expensing stalled in Congress, orders have slowed.

- CEO Michele Clarke and COO Bret Halley made the case for R&D expensing, interest deductibility and a return to full capital investment expensing. Without these, they said, job growth and America’s manufacturing competitive edge are at risk.

- Skilled workers needed: Despite its success, Valley Forge says finding skilled workers is a constant struggle. Immigration reform is a must to secure the right talent pipeline, said Clarke. “Did you notice our engineers? Most of them are under 30 because we’re snatching them right out of college,” added Clarke. “The engineering talent in this country is dwindling, and we’re not authorizing enough green cards. I, myself, was a green card holder before I became a citizen.”

Policy roadblocks: The NAM’s visit to Rio Tinto’s Resolution Copper site highlighted the urgency of permitting reform in the face of critical mineral needs.

- Copper’s critical role: Copper is essential for clean energy. Electric vehicles, solar power grids and wind turbines all demand huge quantities. Yet, the U.S. remains heavily reliant on imported copper, jeopardizing progress.

- Massive potential: The domestic solution lies within the stalled Resolution Copper mine. With its potential to supply 25% of U.S. copper demand, it’s poised to be a key piece of the puzzle.

- Project in limbo: Despite a 350-strong workforce modernizing and maintaining the mine, permitting delays stifle the project’s full impact.

- Sustainable practices: “Resolution Copper is the future of eco-conscious mining,” said NAM Managing Vice President of Brand Strategy Chrys Kefalas, who toured the site. “Their team innovates sustainable practices, leads in water conservation and even supplies 7 billion gallons of water to Arizona farms. And what is more, it isn’t just the facts of the matter or what you saw that drives this point home, but the people who have worked on the site for years make all that clear with the pride they have about the project and their determination to see Resolution Copper through to making lives better for everyone.”

- Jobs and growth: Led by President and General Manager Vicky Peacey, the project promises to contribute $1 billion annually to the economy and more than 1,500 Arizona jobs. “This is about people, jobs and supply chains; and it’s also about realizing clean energy ambitions at the speed and scale that climate goals demand,” said Kefalas.

The bottom line: “The future of U.S. manufacturing might hinge on these contrasting stories. Are we a nation that champions innovation, attracts and keeps the brightest here, supports our manufacturers and tackles climate goals with homegrown solutions, or one that stalls progress in its own backyard,” said Timmons.

- “Arizona is at the epicenter of American manufacturing’s next chapter, and with smart policies and fewer unforced errors at the federal level, we can clear the runway for growth,” added Seiden.

Manufacturing Leaders: Congress Must Act Now

It’s imperative for the strength of not only manufacturing in the U.S. but democracy worldwide that Congress move now to advance a security package and government funding, said NAM President and CEO Jay Timmons, Johnson & Johnson Executive Vice President and Chief Technical Operations & Risk Officer and NAM Board Chair Kathy Wengel and Rockwell Automation Chairman and CEO and NAM Board Vice Chair Blake Moret on Monday.

What’s going on: “For the strength of our democracy here at home and the protection of democracy around the world, manufacturers are calling on Congress and President Biden to act swiftly to keep the government open, pass pro-growth tax provisions, secure our border and approve urgently needed aid for Ukraine,” the three manufacturing leaders told Congress ahead of Biden’s meeting with congressional leaders.

Why it’s important: In March 2022, shortly after Russia’s invasion of Ukraine, the NAM Board passed a unanimous resolution condemning the act and expressing solidarity with the Ukrainian people in their fight for independence.

- In February 2023, Ukrainian President Volodymyr Zelenskyy spoke to the NAM Board in a speech to the American business community. “We will prove that democracy is stronger than tyranny,” Zelenskyy said in that address. “When Russia loses, we will prove that terrorist states cannot overcome the power of a united democratic world.”

What should be done: Timmons, Wengel and Moret hammered home the criticality of swift action by Congress.

- “With time running short, manufacturers are looking to our leaders to act. They can address all of these priorities. In fact, they must address them all—for the future of our industry, the security of our country and the defense of democracy.”

NAM Leadership Kicks Off Competing to Win Tour in South Carolina

Washington, D.C. Today, the National Association of Manufacturers kicked off its 2024 Competing to Win Tour in South Carolina. NAM President and CEO Jay Timmons and NAM Board Chair and Johnson & Johnson Executive Vice President and Chief Technical Operations & Risk Officer Kathy Wengel visited Milliken & Company and Springs Creative Products Group to hear from team members on the shop floor on the issues impacting their businesses.

“Manufacturers are fueling the U.S. economy and driving innovation to create a better future for everyone. We’re here in South Carolina to showcase the people and stories behind our industry, and to translate their perspectives into action that will make our industry and country stronger. Building these strong relationships beyond Washington, D.C., in the cities and states driving our sector deepens our understanding of regional challenges and reinforces the NAM as the leading voice representing all manufacturers, large and small,” said Wengel.

Tomorrow, Timmons will deliver the 2024 NAM State of Manufacturing Address, in which he will provide the industry’s assessment of manufacturing in the United States, as candidates from all sides work to claim the manufacturing vote in the 2024 election.

“For more than a decade, the annual NAM State of Manufacturing Address has focused the nation’s attention on the industry that is the backbone of the American economy, and we are on this tour to hear from the people making decisions on how to grow their businesses every day. Lawmakers from all parties want to claim they stand with manufacturers, but we judge them not by their words but by their deeds. So manufacturers across America have a message for Washington: we are here to hold all candidates and leaders accountable. It takes leadership from both parties to ensure manufacturers have the conditions to thrive and invest in communities across the country. If they fail to act, they will fail the 13 million people who make things in America,” said Timmons.

Timmons will also highlight the challenges facing manufacturers in America and the urgent need to enact a competitiveness agenda that addresses pressing issues, including the looming tax hikes on small manufacturers, the need to expand trading opportunities, the regulatory onslaught from federal agencies, the failure of Congress to address immigration reform and the threats to our energy security and supply chains.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.85 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

NAM: Regulatory Onslaught Disproportionately Hits Small Manufacturers

Small businesses are a critical part of both manufacturing and the U.S. economy at large, but the federal government’s costly regulatory onslaught is putting their continued existence at risk, the NAM told House lawmakers Wednesday.

What’s going on: “In the manufacturing sector, the majority of firms are small,” NAM Vice President of Domestic Policy Brandon Farris told the House Committee on Small Business during the hearing “Burdensome Regulations: Examining the Impact of EPA Regulations on Main Street.”

- “These firms are the backbone of the manufacturing supply chain, often producing key components for larger firms … [but] manufacturing faces significant headwinds in the form of the cost, complexity and uncertainty associated with overreaching and burdensome federal regulations.”

Why it’s important: The seemingly endless conveyor belt of new federal rules for the industry is costing manufacturers “shocking” amounts, disproportionately imperiling manufacturers—small ones in particular, Farris continued.

He cited NAM data finding that:

- The federal cost of regulations for manufacturers in 2022 was roughly $350 billion, a 25% increase from 2012; and

- The average manufacturer in the U.S. pays $29,100 per employee per year to comply with federal rules, while for the average small manufacturer, that price is $50,100.

Where it’s coming from: Farris cited other recent examples of onerous federal rulemaking, including:

- The Environmental Protection Agency’s recently finalized update to the National Ambient Air Quality Standard from 12 micrograms per cubic meter of air to 9 micrograms, a level approaching naturally occurring levels in many parts of the U.S., according to Farris, and one that “will make manufacturing in the U.S. less competitive globally”;

- The Department of Energy’s recent freeze of liquefied natural gas export permits, which, given increased European reliance on U.S. LNG since the start of Russia’s war in Ukraine, risks “leav[ing] our allies [and] our manufacturers in the cold”; and

- The Securities and Exchange Commission’s proposed climate disclosure rule, which “would increase manufacturers’ compliance costs dramatically, divert resources from job creation and growth, expose companies to increased liability, reveal proprietary and confidential information and ensnare wide swaths of the manufacturing supply chain.”

What must be done: Manufacturers aren’t asking legislators to cut corners, Farris said.

- Rather, they are seeking “regulatory certainty that can guide investment decisions and ensure that this country’s economic competitiveness is not outpaced or outflanked or overtaken by nations that do not share our values.”

To learn more about the high cost of overregulation, visit Manufacturers for Sensible Regulations, a coalition created by the NAM and members of the NAM’s Council of Manufacturing Associations and Conference of State Manufacturers Associations that’s intended to address the recent regulatory onslaught from federal agencies.

What’s Ahead for Manufacturing in 2024?

Getting a solid forecast of the year’s key issues in manufacturing can help your business prepare for anything. A panel of experts recently shared their 2024 outlook in the webinar “What’s Ahead for Manufacturing in 2024?” hosted by the Manufacturing Leadership Council, the NAM’s digital transformation arm.

They offered insights on the 2024 manufacturing economy, legislative climate, digital trends, resilience strategies and more.

Economic outlook: NAM Chief Economist Chad Moutray provided a manufacturing economic update.

Key takeaways:

- The NAM Q4 2023 Manufacturers’ Outlook Survey revealed that more than 66% of member companies have a positive economic outlook for 2024, yet opinions are mixed on whether there will be a recession.

- The top economic challenge this year will be the workforce, with the labor market cooling substantially but remaining tight, Moutray said.

- Private manufacturing construction spending is at an all-time high of $210 billion thanks to the production of semiconductors, electric vehicles and batteries, and general reshoring.

- Risks this year include geopolitical turmoil, slow global economic growth, cost pressures, talk of a recession and labor issues, among others.

Policy perspective: NAM Vice President of Domestic Policy Charles Crain gave an overview of the current climate in Washington, D.C., and the NAM’s legislative priorities.

Key takeaways:

- The NAM will continue its focus on tax policy following House passage of an NAM-supported bipartisan tax package that would reinstate three manufacturing-critical tax provisions.

- Manufacturing is facing a regulatory onslaught, with the average manufacturer paying $29,000 per employee per year due to unbalanced, burdensome regulations, according to a recent NAM-commissioned study.

- Artificial intelligence is a hot topic on Capitol Hill, with 60 AI-related bills introduced in Congress last year. The NAM is working to help policymakers understand the benefits of AI, including safety, worker training, product design and development, and efficiency.

Manufacturing 4.0 Trends: MLC Senior Content Director Penelope Brown offered a look at digital manufacturing trends on the horizon.

Key takeaways:

- Manufacturers can expect to see a broader adoption of existing AI applications, including predictive/preventative maintenance, improved processes and enhanced productivity.

- According to the MLC’s recent Smart Factories and Digital Production survey, 65% of manufacturers anticipate their level of M4.0 investment this year will stay the same as last year.

- Other trends to watch include the rise of global partnerships such as Catena-X and CESMII, digitized supply chains and reshoring.

Resilience perspective: Cooley Group President and CEO (and MLC Board of Governors Chair) Dan Dwight shared his approach to resilience in 2024 and the years to come.

Key takeaways:

- Business leaders should prioritize agility and adaptability, even if it means admitting to suboptimal results that require redirection.

- Resilience doesn’t mean perfection; it means learning from failures.

- AI and machine learning contribute to resilience by building out end-to-end visibility across an organization—from vendors to manufacturing operations to customers.

For additional details from these experts, watch “What’s Ahead for Manufacturing in 2024?”

NAM Pushes for Transparent Conclusion of Tariff Review

The Biden administration is nearing the end of a lengthy review on whether to adjust or extend tariffs on a variety of goods and materials from China—and the NAM is working to make sure manufacturers’ voices are heard.

The background: Following a 2017 investigation into China’s trade practices, the Trump administration put in place a set of levies on imported goods from China—called Section 301 tariffs—intended to incentivize change in practices by China that were found by the Office of the U.S. Trade Representative to be “unreasonable or discriminatory.”

- These included policies and practices related to technology transfer, intellectual property and innovation.

The review: In May 2022, USTR initiated a legally required four-year review of the Section 301 tariffs that focused on tariff efficacy in changing Chinese discriminatory practices and the impact of the tariffs on the U.S. economy, workers and consumers, among other considerations.

- More than 18 months later, the review remains unfinished. The NAM is urging USTR to finish and publish it—and to take actions that reduce the burdens on manufacturers while maintaining appropriate leverage to incentivize China to adhere to bilateral and multilateral commitments.

- “Ideally, USTR will conclude the four-year review in the next few weeks and make the results public,” said NAM Senior Director of International Policy Ali Aafedt. “We would like to see the results reflect the 1,498 public submissions USTR received during the process and the reduction or removal of some of the tariffs that are harming manufacturers in the U.S. more than they’re creating leverage on China.”

The exclusions: There are 429 existing exclusions from the tariffs—including 77 COVID-19-related products and 352 reinstated exclusions—which are in effect through May 31.

- The NAM has also been pushing for a new process that allows manufacturers to ask the government to exclude specific products they need from the tariffs.

- “The NAM has been calling for a new, fair and transparent Section 301 tariff exclusion process that would allow all U.S. stakeholders an opportunity to seek relief or weigh in on the existing tariffs,” said Aafedt. “The last opportunity to petition USTR for relief from Section 301 tariffs was in 2020, and a new exclusion process will help to better align the tariffs with U.S. economic goals.”

The outlook: Reports such as this one from The Wall Street Journal indicate that the Biden administration will look to rebalance the tariffs, potentially reducing those that are not in the U.S. interest and raising tariffs on other items, including, potentially, on imports from China in the electric vehicle and battery sectors.

- “The NAM will continue to push for a more strategic approach,” said Aafedt.

If your company has interest in a specific existing exclusion, USTR is seeking feedback here by Feb. 21.

Immigration Reform and Border Security Critical to Manufacturers’ Success in America

Washington, D.C. – Following the Senate introduction of the Border Act of 2024, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“For years, manufacturers have called on Congress to fix our broken immigration system, and the need for a solution at the border has only grown more urgent. This bill is neither perfect nor comprehensive, but it is important to take steps to address immigration reform and border security consistent with our plan, ‘A Way Forward.’

“Manufacturers believe the Senate’s legislation clears some critical tests: Does it make us more secure than we are today by tackling the border crisis? Yes. Does it address our ongoing worker shortage through strengthening the visa program? Yes. And does it protect democracy by supporting our allies overseas? Yes.

“Anytime Congress shows progress on sensible policy, it is a positive development for our country. The bipartisan group of Senate leaders deserves great credit for forging a plan on one of the most complicated issues facing our nation, and we appreciate the leadership’s support for this critical work.

“The NAM will work with both chambers and the administration to enact meaningful change on the critical issues of immigration and border security.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.85 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

House Passes NAM-Supported Tax Package

Manufacturers scored a major victory last night when the House passed a bipartisan tax package containing provisions critical to the industry.

What’s going on: The House voted 357–70 to pass the bipartisan Tax Relief for American Families and Workers Act. The bill includes three important manufacturing priorities:

- Restoring immediate R&D expensing for domestic research

- Reinstating full expensing (also known as 100% accelerated depreciation) for businesses’ capital investments

- Returning the U.S. to a pro-growth interest deductibility standard

What it means: The measure will enable manufacturers to invest in their businesses, create jobs and compete in the global marketplace.

- The bill is particularly important for small and medium-sized manufacturers, many of which experienced significant tax increases as a result of the expiration of these pro-growth provisions.

- “While it was once a paid expense, R&D is now a cost that many small businesses cannot afford,” said Carol Miller (R-WV), in a speech on the House floor last month.

- The overwhelming majority—89%—of respondents to the NAM’s Q4 2023 Manufacturers’ Outlook Survey said higher tax burdens on manufacturing would make it more difficult for them to hire, buy new equipment and expand their facilities.

What’s next: It’s critical that the Senate now also pass the measure, the NAM said.

- “Manufacturers thank [House Speaker Mike Johnson (R-LA)] and [House Ways and Means Committee Chairman Jason Smith (R-MO)] for their leadership in passing the Tax Relief for American Families and Workers Act—and the bipartisan work in the House and Senate to secure progress for America’s manufacturing workers,” said NAM President and CEO Jay Timmons in a social post Wednesday night. “Manufacturers are now counting on the Senate to act quickly to restore these provisions that are absolutely critical to strengthening America’s competitiveness and growth of manufacturing in America.”

- Added Ketchie President and Owner and NAM Small and Medium Manufacturers Group Chair Courtney Silver, “This just isn’t about numbers on my financial statements and my tax returns—this is about taking care of the people here [at Ketchie] and in communities across this country…. Let’s restore some common-sense tax provisions, and let’s support our American manufacturers across our country.”

House Passage of Tax Priorities a Win for Manufacturers, Counting on Senate to Act Swiftly

Washington, D.C. – Following House passage of the Tax Relief for American Families and Workers Act of 2024, National Association of Manufacturers President and CEO Jay Timmons and Ketchie President and Owner and NAM Small and Medium Manufacturers Group Chair Courtney Silver released the following statement:

“Manufacturers thank Speaker Johnson and Chairman Smith for their leadership in passing the Tax Relief for American Families and Workers Act—and the bipartisan work in the House and Senate to secure progress for America’s manufacturing workers,” said Timmons.

“Manufacturers are now counting on the Senate to act quickly to restore these provisions that are absolutely critical to strengthening America’s competitiveness and growth of manufacturing in America,” Timmons added. “We cannot afford to wait. The cost of delay or inaction will be measured in lost jobs and slower wage growth, along with investment ceded to other countries. Passing this legislation, however, will ensure that small manufacturers, who are the backbone of communities and foundation of America’s supply chain, can continue driving our nation forward.”

“When key tax provisions expired, it wasn’t just businesses like Ketchie that felt the pinch—it was our ability to support and create jobs that took a hit,” said Silver. “I thank Speaker Johnson and Chairman Smith for their efforts to ensure passage of the Tax Relief for American Families and Workers Act. This isn’t just about numbers on financial statements; it’s about taking care of people who make things in America and work at small manufacturing companies across our country.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.85 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.