Maryland Manufacturer to Increase Hiring, Invest

Maryland’s Marlin Steel Wire Products has long been a leader in its industry—and, because of tax reform, it plans to bring new jobs to its Baltimore facility and invest in the latest technology that will keep it ahead of the competition.“From the moment tax reform was announced, Marlin Steel decided we’re all in,” said Marlin Steel President and Owner Drew Greenblatt. “We knew the economy would crank up and that there would be optimism—but it was like a gun shot off.”

First on the docket? Investing in the latest technology, to increase efficiency and help Marlin Steel meet skyrocketing demand for its products.

“We’ve reconfigured our factory and bought six robots from Arkansas, Ohio and Minnesota,” said Greenblatt. “We largely buy products that are made in America—American robots, American steel.”

Marlin Steel’s new technology includes a 121-ton stamping press from Ohio, which was delivered in July, as well as a robotic threader from Chicago, which was delivered at the end of August.

“Every order for new technology went out because I trusted that House Speaker Paul Ryan, Senate Majority Leader Mitch McConnell and President Donald Trump would come through on their tax reform promises,” Greenblatt added. “And they did.”

In fact, Marlin Steel invested in so much new technology that it had to bring in a utility company to run new wires throughout its facility—adding seven and a half times the maximum power so it could handle the latest equipment.

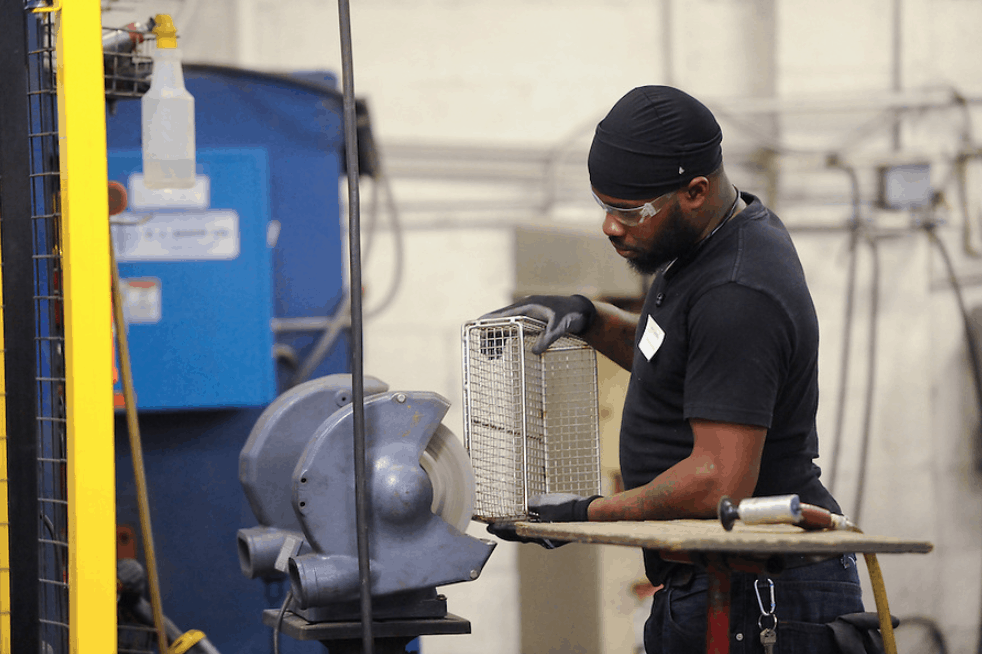

Adding new equipment to deal with rising demand also means hiring new employees. Marlin Steel plans to increase dramatically the size of its staff by more than 20 percent. Many of these employees are formerly unemployed steelworkers from Baltimore—and Greenblatt takes special pride in helping them reenter the workforce.

“We’re helping bring people in Baltimore back into the middle class,” he said. “That’s what this is all about. We’re giving our employees the extraordinary tools they need to run circles around other countries, to make them more productive than workers in other countries.”

Already, Marlin Steel’s investment in productivity is helping bring business back from overseas. Greenblatt explained that a big customer recently closed a factory in India and moved those 15 product lines to Marlin Steel’s Baltimore facility—specifically because of Marlin Steel’s superior efficiency and quality.

“Suddenly, the U.S. is competitive again,” said Greenblatt. “We’re so enthusiastic about the future opportunities we have, thanks to tax reform.”