Final Heavy-Duty Tailpipe Rule Presents Challenges

The Environmental Protection Agency’s new heavy-duty tailpipe emissions rule is unrealistic and unfeasible, the NAM said Friday.

What’s going on: “The rule—proposed in April 2023—is part of the ‘Clean Trucks Plan’ unveiled in 2023, which includes light-duty tailpipe and nitrogen oxide rules,” Bloomberg Law (subscription) reports.

- “The[se] ‘Phase 3’ standards build on previous phases of a broader regulatory program to stem greenhouse gas emissions from vehicles such as delivery trucks, long-haulers, and buses.”

- The Phase 1 rule was finalized in 2011, and the Phase 2 rule in 2016.

Why it’s problematic: While the new regulation grants automakers more time for implementation than previous versions did—thanks to input from manufacturers and their advocates, including the NAM—it still “fails to reconcile with the realities of current U.S. infrastructure,” according to an NAM social post.

- “Critical permitting reforms to strengthen transmission systems and a technology-neutral approach for manufacturers are essential to reaching U.S. climate goals,” the NAM wrote.

What should be done: Congress must reform the broken U.S. permitting system so we can build the electric vehicle charging station infrastructure required to implement a rule of this magnitude, the NAM said earlier this month.

NAM: OSHA “Walkaround” Rule an Example of Regulatory Onslaught

The U.S. Occupational Safety and Health Administration’s newly finalized “walkaround rule” is unlawful and will not further the agency’s mission of ensuring safe working conditions, the NAM said after the rule’s release.

What’s going on: The long-awaited final rule, which goes into effect May 31, states that “workers may authorize another employee to serve as their representative or select a non-employee,” according to the Department of Labor.

- The policy broadens the basis upon which a non-employee representative may be deemed “reasonably necessary to the conduct of an effective and thorough inspection.”

Why it’s problematic: In addition to having little to do with making workplaces safer, the new policy violates OSHA’s own mandate—and, quite possibly, manufacturers’ constitutional rights, the NAM said.

- The “rule does nothing to advance OSHA’s mission of ensuring safe working conditions,” said NAM Chief Legal Officer Linda Kelly. “Forcing businesses to accommodate third parties with no safety expertise in their facilities infringes on employers’ property rights, invites new liabilities and introduces elements of chaos and disruption to safety inspections. … [It also] clearly violates OSHA’s statutory mandate to conduct inspections within ‘reasonable limits and in a reasonable manner’ with ‘minimum burden’ on employers, and potentially violates manufacturers’ constitutional rights.”

Next steps: The NAM is weighing legal action to reverse the final rule.

Skilled Trades See Interest Uptick

More young people are choosing skilled trade jobs after high school, The Wall Street Journal (subscription) reports.

What’s going on: “Enrollment in vocational training programs is surging as overall enrollment in community colleges and four-year institutions has fallen. The number of students enrolled in vocational-focused community colleges rose 16% last year to its highest level since the National Student Clearinghouse began tracking such data in 2018. The ranks of students studying construction trades rose 23% during that time, while those in programs covering HVAC and vehicle maintenance and repair increased 7%.”

Why it’s important: The trades, including manufacturing, have experienced a worker shortage in recent years as the older generation of employees retires.

- Finding and retaining quality talent is consistently a top business challenge among manufacturers, according to the NAM’s Manufacturers’ Outlook Survey, a quarterly polling of the industry.

- But now, trade-apprenticeship demand is surging, perhaps a signal that positions will start to fill.

Perception change: For many years the vocational education wing of one high school in Sheboygan, Wisconsin, was called “greaser hall,” but lately that’s started to change, a counselor there told the Journal.

- “[B]usinesses have raised funds and donated new equipment, including robotic arms … [and] those classrooms now sit at the building’s main entrance. ‘There’s still a presumption that four-year college is the gold standard, but it doesn’t take as much work to get people to buy into the viability of other options,’ [he said].”

The last word: Indeed, the Manufacturing Institute, the NAM’s 501(c)3 nonprofit workforce development and education affiliate, is seeing significant growth in its FAME initiative, an earn-while-you-learn training program with more than 40 chapters in 16 states—and more forming all the time. FAME, which was founded by Toyota and is now led by the MI, is truly the American model of skills training, according to MI President and Executive Director Carolyn Lee.

- “FAME is training thousands of global best technicians nationwide and the number of program participants is on the rise,” she said. “This is good news for manufacturing, which sorely needs talent to continue to make the many, many things people use every day.”

New NAM Ad: Senate Must Pass Tax Bill Now

Earlier this year, the House passed legislation including key NAM tax priorities. Now it’s time for the Senate to do the same.

That’s the message of a new NAM digital ad campaign launched today and set to run over the next several weeks.

What’s going on: The 30-second TV ad—which will stream in Washington, D.C., and in the key states of Idaho, Kentucky, Louisiana, Oklahoma, New York and New Hampshire—asks viewers to urge the Senate to pass the Tax Relief for American Families and Workers Act, which cleared the House by a bipartisan vote in January.

- The legislation restores three key pro-growth tax provisions from the 2017 Tax Cuts and Jobs Act that expired in 2022: immediate expensing for domestic R&D, enhanced interest deductibility and full expensing.

The background: Earlier this month, Courtney Silver, president and owner of Ketchie and chair of the NAM Small and Medium Manufacturers Group, told the Senate Finance Committee about the impact the three provisions’ expiration has had on her family-owned precision machining company.

- “In the years following the TCJA, I was able to make a higher level of investment because I knew our tax code was going to have a baseline of certainty,” she said. “Today, however, I am unable to make these investments because of the uncertainty that Congress will address the expired TCJA provisions. . . . Because I am unable to realize the full deduction of my investment within the year I purchase it, the investment seems too risky and irresponsible.”

What’s needed: Senate Majority Leader Chuck Schumer (D-NY) has taken an early procedural step to put the House-passed legislation on the Senate’s calendar. But more needs to happen, and soon, the NAM’s ad tells viewers.

- “Vital tax provisions are expiring, harming our ability to compete globally and invest in new factories and equipment,” the ad says. “The House has done its job and restored these provisions with overwhelming support. The Senate needs to act now.”

Innovation First: How Oshkosh Corp.’s 107 Years of Experience Deliver Innovative Solutions

Oshkosh Corp. manufactures a wide array of purpose-built vehicles and equipment, but at its heart, it’s an industrial technology company focused on engineering, President and CEO John Pfeifer told the NAM recently.

“If you look at us up close, we’re really an engineering company,” Pfeifer said. “If you look at a fire truck up close, you’d be amazed at the amount of design engineering [that goes into] to this machine.”

A fire truck boom: Fire trucks are indeed a big part of business at the 107-year-old company, headquartered in its namesake Oshkosh, Wisconsin. In fact, there’s such a demand for the vehicles—which Oshkosh offers in more than 300 different shades of red—from municipalities throughout the U.S., the firm has a two-and-a-half-year backlog.

- The major reason: rising home values. Counties and towns get their revenue from property tax receipts. When those are strong, as they have been in recent years, the governments can afford to upgrade their fleets—which they’re now doing in earnest, Pfeifer said.

Innovation = safety + productivity: They’re going to Oshkosh for the very reason Pfeifer considers the company first and foremost an engineering outfit. In addition to fire and other municipal and vocational trucks, the company manufactures defense, construction and aviation ground support equipment.

- “We’re able to accelerate innovation because of our technical capabilities as a company,” he explained. “We’re able to electrify things that are not supposed to be electrical—like a 40,000-pound municipal fire truck.”

- Worldwide, Oshkosh employs a team of between 1,600 and 1,700 engineers just for design work, according to Pfeifer.

- In any product it makes, Oshkosh’s primary concern is improving the safety and productivity of “the everyday heroes who do the hardest work. Military, firefighters, mail carriers—those are the people who use our products, and that’s why innovation matters. Our products allow them to be more productive and a lot safer.”

Legislation-supported growth: But it’s not just those vehicles that are seeing exploding demand from customers.

- Historic federal investments, such as those in the CHIPS and Science Act and the Bipartisan Infrastructure Law and the Inflation Reduction Act, “have spawned huge infrastructure projects,” Pfeifer added. “So it doesn’t matter what you’re producing; you can’t produce it without our equipment.”

- Last year, contractors in North America kicked off approximately $350 billion worth of projects, with electric vehicle and semiconductor facilities and data centers all acting as drivers of that growth.

Speaking of EVs: Oshkosh has a lot to boast about in the EV space.

- It was recently chosen by the U.S. Postal Service to design the agency’s Next Generation Delivery Vehicle, a mail van “customized specifically for the needs of mail carriers,” according to the Oshkosh website. The vehicle’s propulsion platform can accommodate both traditional internal-combustion and battery-electric engines.

- And in addition to having developed a lithium-ion battery-powered refuse and recycling vehicle, Oshkosh also manufactured the first electric fire truck in service in North America. It’s the Pierce® Volterra™ Pumper, and the Madison Fire Department’s fleet in Madison, Wisconsin, has a purchase order agreement for it following a highly successful 18-month placement of one of the Pumpers.

Coming up: What’s next for Oshkosh? With its healthy balance sheet, the company is investing for the long haul, Pfeifer told the NAM.

- “We’re hiring a lot and opening new facilities,” Pfeifer continued, adding that Oshkosh subsidiary JLG Industries Inc.—which makes the popular SkyTrak® telehandler hydraulic lift machine—is expanding its 500,000-square-foot manufacturing facility in Jefferson City, Tennessee, and Oshkosh recently opened new plants in Spartanburg, South Carolina, and Murfreesboro, Tennessee.

The last word: The firm is also focusing on strategic acquisition work, Pfeifer said.

- Last year, it purchased AeroTech, a company that makes cargo loaders and other airport ground support equipment.

- “We’re very patient, but when we see the opportunity to acquire a business and enter a new product category or adjacent market where we can make a difference, we do it.”

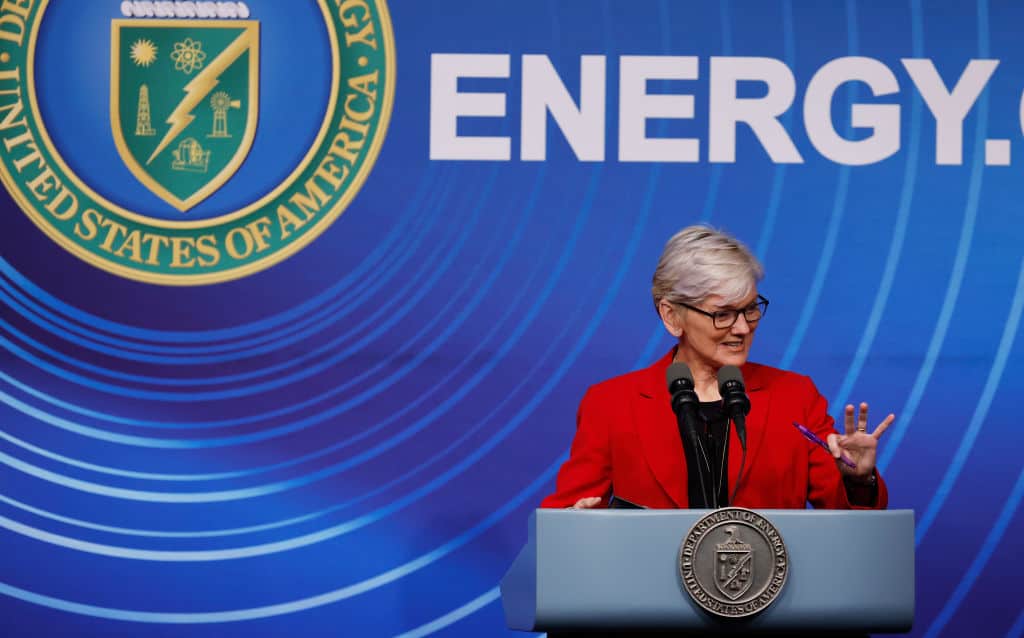

DOE to Award Record-Setting Decarbonization Funds

The Department of Energy on Monday announced record-setting funding aimed at decarbonizing energy-intensive sectors, POLITICO Pro (subscription) reports.

What’s going on: The nearly $6 billion in “funding from the Democrats’ climate law and the bipartisan infrastructure law for industrial decarbonization will be spread across 33 projects and 20 states,” where it “will apply to some of the highest-emitting industrial manufacturing sectors—often described as ‘hard-to-decarbonize’ industries—including iron and steel, aluminum, cement, concrete, chemicals, food and beverages, and pulp and paper.”

Where it’s coming from: The money will be drawn from funds set aside under the Inflation Reduction Act ($5.47 billion) and the Bipartisan Infrastructure Law ($489 million).

Why it’s important: The many projects to be funded—which include groundbreaking recycling initiatives, hydrogen-use projects, decarbonization of thermal processes and more—will remove approximately 14 million metric tons of emissions every year, the DOE estimates.

- Five of the highest-dollar-value projects, at half a billion dollars each, “are focused on decarbonizing cement, concrete, aluminum, iron and steel.”

- The work will take place in five states—Indiana, Ohio, California, Iowa and Mississippi—and a still-to-be-determined spot on the Mississippi River Basin.

- Many of the projects are spearheaded by NAM members, who have been critical in innovating decarbonization efforts from within the industry.

The NAM’s take: “Manufacturers are innovating and making tremendous investments to decarbonize their processes and products,” said NAM Vice President of Domestic Policy Brandon Farris. “It is great to see the Department of Energy recognize multiple NAM members for their industry-leading initiatives.”

Baltimore Bridge Collapse to Hit Shipping, Port Jobs

Vessel traffic in and out of the Port of Baltimore—which contributes $15 million a day in economic activity, Business Insider reports—was suspended Tuesday after a container ship hit the Francis Scott Key Bridge in the early morning. The collision caused the bridge to collapse, sending at least seven vehicles and their occupants into the Patapsco River, according to the Baltimore Sun (subscription).

What’s going on: “Officials, who spoke amid a continuing and massive search and rescue mission, said the port was not shut down and remained open to process trucks inside terminals.”

- Other ports are likely to be able to absorb container ships headed for Baltimore, The New York Times (subscription) reports.

Why it’s important: “The port, which generates more than 15,300 direct jobs, had rebounded from global supply chain difficulties and disruptions during the coronavirus pandemic and hit records last year for handling cargo,” according to the Baltimore Sun. “It is the nation’s 16th busiest port, ranking first for volume of autos and light trucks, roll-on/roll-off heavy farm and construction machinery, imported sugar and imported gypsum.”

- Baltimore is the closest Atlantic port to major Midwestern manufacturing hubs.

- Truckers are concerned about increased congestion resulting from the closure, “particularly because deliveries such as hazardous material loads cannot travel through Interstate 895 or I-95 tunnels.” Trucking companies are already warning customers of delays for shipments going through the Mid-Atlantic, according to The Wall Street Journal (subscription).

- In addition to affecting consumers in the Baltimore area, the traffic stoppage is likely to affect jobs at the port.

An Engineer Looks to the Future at ExxonMobil

It was an internship in modern manufacturing that changed Bobi Simonsen’s view of the industry—and gave her a sense of how many different kinds of opportunities were available.

“I remember school projects where I would just picture an engineer with a hard hat doing calculations,” said Simonsen. “I didn’t realize how much creativity and collaboration is involved in engineering. There is way more complexity than I had ever realized.”

A new path: Shortly after that internship, Simonsen got connected with ExxonMobil through the University of Texas—and she hasn’t looked back since.

- Today, she’s a technical supervisor at the largest polyethylene site in the world, leading teams of engineers, chemists and technicians who perform experimental commercial-scale trials and improvement projects on the tough synthetic resin used in bags, containers and other packaging.

A sense of purpose: Simonsen is particularly interested in opportunities to support sustainability and sees manufacturing as the perfect place to make an impact.

- “I know young people are really passionate about sustainability, making a difference and having a purpose, and all of those are things you can do in manufacturing, especially at a place like ExxonMobil,” said Simonsen. “We are global, we are integrated and we have the resources and scale to impact an entire industry. That’s the reason I came to work here.”

A push for parity: Simonsen also sees how the lack of women in science, technology, engineering and math feeds into a shortage of women in manufacturing, and she’s eager to see more young women find their way into the field.

- That’s why she leads industry meet-and-greet events on behalf of ExxonMobil at the University of Texas, volunteers at “Introduce a Girl to Engineering Day” events for K-12 students in Austin and Houston and hosts lunch-and-learn sessions with UT’s Society of Women Engineers and the American Institute of Chemical Engineers.

- She also leads ExxonMobil’s SWE conference team, who recruit, share sessions and lead “Invent It Build It” outreach activities through SWE.

- “We do a good job of recruiting candidates who reflect the diversity of the pipeline; my classes in college were 30% women, and that’s translating to the same 30% who make their way into ExxonMobil manufacturing,” said Simonsen. “But that’s not 50%, which is why it’s vital to engage women and minorities to get interested in STEM so we can bring them into classes and then the workforce as they graduate.”

New visibility: Recently, Simonsen was named an Emerging Leader in Manufacturing by the 2024 Women MAKE Awards, a distinction for a select few women under the age of 30 who have achieved rare accomplishments at the start of their careers in manufacturing.

Advice for women: While most workers in the industry are still men, Simonsen encourages women to consider the broad range of opportunities available in manufacturing.

- “I would say, ‘Try it,’” said Simonsen. “Consider trying it, even for a short period like an internship. Because if you step in, and you like it, you can find yourself working on the biggest challenges in the world.”

Q&A: What You Need to Know on Tax Policy

Earlier this year, the House passed the Tax Relief for American Families and Workers Act, and the bill is now with the Senate to consider. NAM Vice President of Domestic Policy Charles Crain discusses what’s included in the bill, why the provisions matter to small and medium-sized manufacturers, other tax policies the NAM is focusing its advocacy efforts on and how SMMs can get involved.

Q: There is a major tax package moving through Congress. Can you explain what is included in the legislation?

Crain: “The Tax Relief for American Families and Workers Act includes three of the NAM’s top tax priorities: the ability to immediately deduct domestic R&D expenses, enhanced interest deductibility on business loans and the ability to fully deduct the cost of capital investments in the year acquired (full expensing). All three of these provisions were implemented by the 2017 Tax Cuts and Jobs Act.”

Q: What exactly are these provisions and why do they matter to SMMs?

Crain: R&D – “For almost 70 years, the U.S. tax code allowed businesses to fully deduct their R&D expenses in the same year they were incurred. But starting in 2022, businesses were required to deduct those expenses over a period of years, making it more costly to conduct R&D in the U.S.”

Interest Deductibility – “Many manufacturers need to borrow funds to finance long-term investments in equipment and facilities. The interest that businesses pay on these loans is generally tax deductible, subject to a cap. Prior to 2022, the cap was based on a company’s earnings before interest, tax, depreciation and amortization (EBITDA); now, it’s based on a company’s earnings before interest and tax (EBIT). Lowering the cap limits the amount of interest that companies can deduct—effectively imposing a tax hike on manufacturers that finance job-creating capital projects.”

Full Expensing – “Manufacturing is a capital-intensive industry. The TCJA allowed companies to immediately deduct 100% of the cost of equipment and machinery in the year purchased—called ‘full expensing.’ But full expensing began to phase out in 2023; it’s currently down to 60% and will be completely eliminated by 2027. That significantly increases the after-tax cost of capital equipment purchases.”

Q: Why is it important for Congress to restore these tax provisions for SMMs?

Crain: “These are provisions that manufacturers, especially SMMs, use to grow their businesses and compete globally. The tax code must be fair and consistent. The first step is addressing these crucial issues.”

Q: What other tax policies is the NAM focusing its advocacy efforts on?

Crain: “We are in the middle of a three-part story. If the TCJA was the first part of the trilogy, the second act is the Tax Relief for American Families and Workers Act—and the grand finale will come in 2025, when many other TCJA provisions expire. Changes that will impact SMMs at the end of 2025 include the expiration of the 20% pass-through deduction, increases in individual income tax rates and a reduction of the estate tax exemption threshold. Without congressional action, this would affect the laws in effect for tax year 2026 and beyond. For SMMs organized as corporations, the corporate tax rate could also be at risk. The NAM is already pushing back, and we know manufacturers are ready to pull out all the stops to prevent them from taking effect in 2026.”

Q: Where can SMMs find more information, and how can they get involved?

Crain: “The NAM has created online action centers for R&D, interest deductibility and full expensing with information on why these issues remain important. NAM members are encouraged to check out these action centers for tools and resources they can use to contact lawmakers on these issues. They need to hear from you! You can also reach out directly to NAM Senior Director of Tax Policy Alex Monié.”

Q: What else do SMMs need to know?

Crain: “There is an old saying in D.C.: ‘Tax bills are hard.’ We have gotten the Tax Relief for American Families and Workers Act through the House, but more work needs to be done in the Senate. And the next 20 months will be an all-out sprint to prevent damaging tax increases from taking effect at the end of 2025. The NAM was successful with the TCJA in 2017—and, I believe, will be successful both this year and next—thanks to our members. Your stories are absolutely crucial to showing that manufacturers kept our promises following tax reform’s passage—and illustrating the economic damage that will happen if R&D expensing, interest deductibility and full expensing aren’t revived this year, or if tax increases are allowed to hit SMMs in 2026. Please reach out to your membership adviser, or to Alex, to share any stories, feedback or ideas as we continue to advocate for pro-growth tax policies for manufacturers in America.”

U.S. Awards Intel Largest Chips Grant

The U.S. will award Intel up to $8.5 billion in grants and as much as $11 billion in loans to expand chipmaking capacity and capabilities in four states, The Wall Street Journal (subscription) reports.

What’s going on: The funds, set aside under the NAM-backed 2022 CHIPS and Science Act to bolster domestic semiconductor production, “will go toward new factories and expansion projects in Arizona, New Mexico, Ohio and Oregon, the Commerce Department said.”

- Spurred by the federal funding, “Intel’s total investment in U.S. projects in the next five years is expected to exceed $100 billion,” according to the Journal, and to create more than 10,000 manufacturing jobs and about 20,000 construction jobs, according to the Commerce Department.

Largest award: The grant to Intel, the largest American chipmaker by revenue, is also the largest CHIPS Act award. It follows a February announcement of a $1.5 billion award to GlobalFoundries Inc.

- The award will support the reshoring of production of leading-edge logic chips, which are “essential to the world’s most advanced technologies like artificial intelligence,” the Commerce Department said.

- President Biden was in Chandler, Arizona, Wednesday to visit Intel’s Ocotillo chip-manufacturing campus.

Why it’s important: “We can’t just design chips; we have to make them in America,” Commerce Secretary Gina Raimondo told reporters on Tuesday, the Journal reports. “It’s an economic security problem. It’s a national security problem. And we’re going to change that.”

How it will work: The funding will be doled out in stages, “according to construction and manufacturing milestones,” the Journal said.

- “In Chandler, Arizona, the money will help to build two new chip plants and modernize an existing one,” CBS News reports. “The funding will establish two advanced plants in New Albany, Ohio, [and] … [t]he company will also turn two of its plants in Rio Rancho, New Mexico, into advanced packaging facilities. And Intel will also modernize facilities in Hillsboro, Oregon.”

The NAM weighs in: Wednesday’s “record, multibillion-dollar award is great news for [Intel] and U.S. manufacturing competitiveness,” the NAM wrote in a social post. “The NAM was a vocal supporter of the CHIPS and Science Act, and we will continue to champion policies that support the expansion of chip production in America.”