A Merck Manufacturer Leads the Way

For Alexandra Bryant-Boose, being a mentor matters—because she’s seen firsthand what good mentorship can accomplish.

From a mentor at a homeless shelter where she and her mother lived for a time, to an eighth-grade science teacher who pointed her toward a scholarship at an engineering summer program, she is grateful for all the people who helped guide her in the right direction.

- “There were so many experiences where someone gave me an opportunity,” Bryant-Boose said.

Today, as an automation specialist at Merck Manufacturing Division, part of Merck in Durham, North Carolina, Bryant-Boose is paying that opportunity forward, making sure that others are able to find their passion and achieve their dreams.

Discovering manufacturing: Bryant-Boose graduated from North Carolina State University with a degree in chemical engineering, a concentration in biomolecular engineering and a double minor in microbiology and biotechnology.

- When the COVID-19 pandemic hit, she began looking at careers at Merck, and in her words, just stumbled onto automation. After doing some research, she was hooked.

- “Automation is like playing investigative journalism or being a detective,” said Bryant-Boose. “Sometimes there’s a problem and no one will know what the issue is—and automation is about looking into the nitty-gritty, getting a little dirty and opening up a system to find what the issue is. That way of thinking and working is what makes me enjoy what I do.”

Educating young people: In 2022, Bryant-Boose launched a project designed to spread opportunities in science, technology, engineering and math to young people who might not otherwise be able to learn about those subjects.

- She started small in 2022, with a program at a local middle school. Last summer, in collaboration between the Society of Women Engineers and Durham Parks & Recreation, the project grew into a STEM summer camp with about 30 Merck volunteers.

- “We hosted 90 kids in three locations who all got that face-to-face interaction with Merck employees,” she said. “It was a lot of work to organize, but it was good to pay it forward. I’m giving kids someone to look up to and helping them figure out where they might go.”

Promoting support: Bryant-Boose is also a talent acquisition lead for the League of Employees of African Descent at Merck. The internal group, which offers both mentoring and reverse mentoring—in which younger employees provide advice and knowledge to executive team members—gives her a chance to both advise and be advised.

- “I like being able to give people advice that I wish I had,” said Bryant-Boose. “At the end of the day, it’s good to be around people who can relate to things you’re going through. And I find that LEAD allows me to do that at Merck.”

Gaining recognition: Recently, Bryant-Boose was named an Emerging Leader in manufacturing by the 2024 Women MAKE Awards, a distinction for a select few women under the age of 30 who have achieved unique accomplishments at the start of their careers in manufacturing.

Offering advice: Some of Bryant-Boose’s best advice is to encourage people— especially women—to find their own mentors.

- “I know coming into what’s historically been a male-dominated field can be intimidating,” said Bryant-Boose. “If you’re a woman considering manufacturing, or actively getting into it, find that person who can be your mentor. Claim them. Go to them when you need someone to talk to.”

Go deeper: To see the full list of 2024 Women MAKE Award Honorees and Emerging Leaders, click here. To learn more about the Women MAKE Awards, click here, and to learn more about the MI’s free Women MAKE Mentorship Program, click here or contact the team at [email protected].

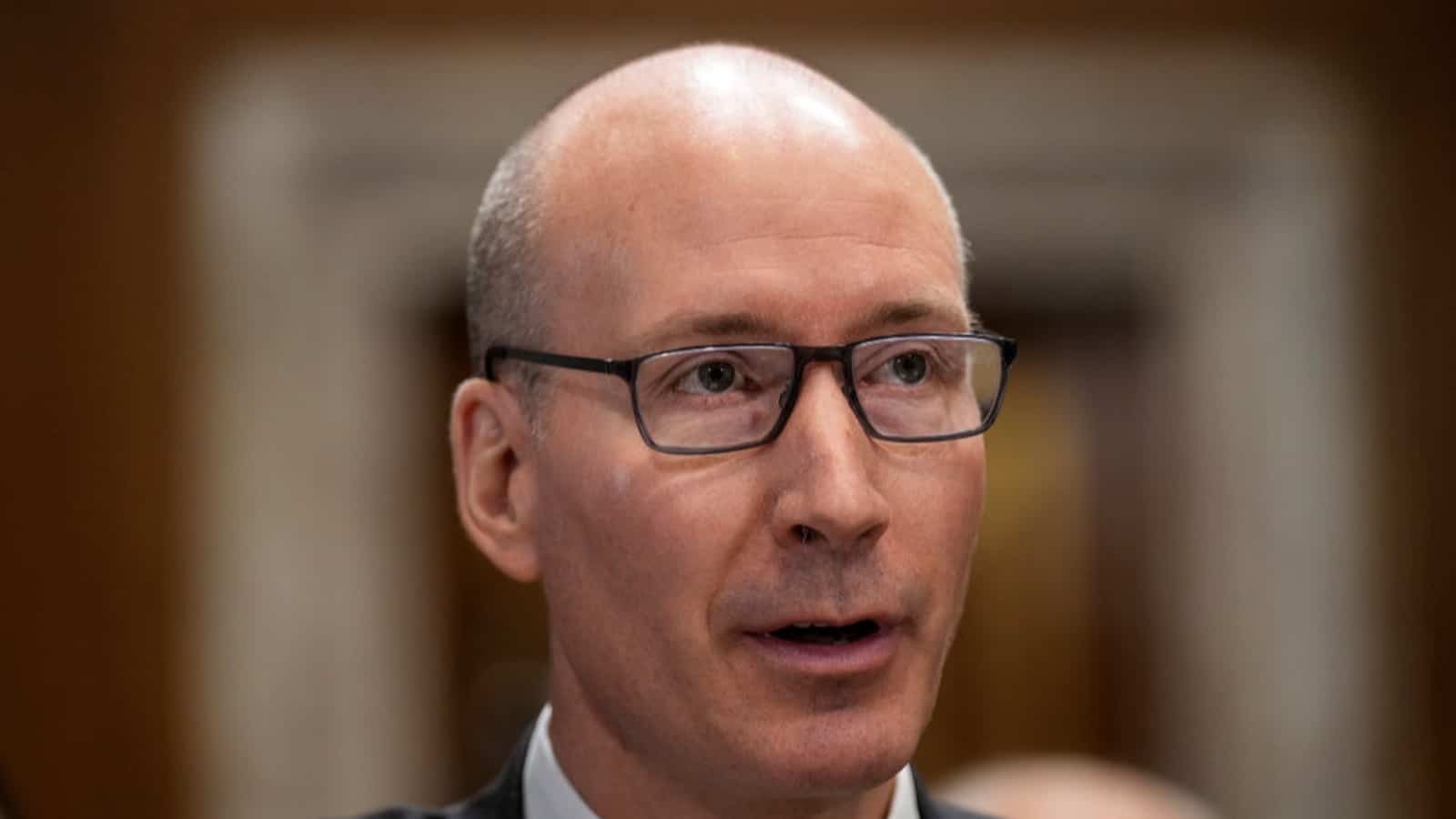

Top DOE Official to NAM: You’re Critical to America’s Energy Future

The Biden administration sees private-sector partners as essential to the future of American energy policy and production, Deputy Secretary of Energy David Turk told NAM board members in Phoenix, Arizona, recently.

What’s going on: “I don’t think we can do anything in the federal government that impacts the real world without enabling, listening to, supporting and trying to be very thoughtful” with private-sector partners, Turk said, calling manufacturers a key force in helping the United States “accelerate our energy independence.”

- In a discussion about energy policy in the clean energy transition—with a focus on nuclear energy, hydrogen and the role of the federal government—Turk took questions and comments from leading figures in the private-sector energy economy on issues ranging from the Biden administration’s freeze on liquefied natural gas export permits, to the need for a robust hydrogen economy, to the implementation of long-awaited transmission infrastructure to ensure energy reliability and affordability.

- The talk also touched on the potential impact of increased natural gas exports on domestic prices and consumers. NAM board members argued that higher exports would not make gas more expensive for U.S. consumers and LNG exports are vital to ensure energy security for our allies.

The conversation: In a roundtable lunch, NAM board members told Turk that the push and pull of the Biden administration’s policies on energy—calling on U.S. producers to increase energy output to reduce consumer prices while calling for an overall reduction in fossil fuel production—makes their goal of increasing American energy reliability and independence more difficult to realize, while creating market gaps that can be filled by cheap energy from Russia and other geopolitical rivals.

“Why did this happen? Why did it come out? How does that achieve any of our shared objectives on the national security stage in terms of climate change?” NAM President and CEO Jay Timmons asked Turk, noting that the Biden administration’s decision to stop approving new export licenses for U.S. LNG undercuts its own stated carbon agenda in the long run.

Turk told NAM board members that U.S. consumers pay roughly one-fifth as much for LNG as those in Asia and Europe, which he called “huge” for economic competitiveness, but still acknowledged that the differential doesn’t accommodate the needs of all manufacturers involved in the energy economy.

“There’s a competitive advantage if our manufacturers are paying less for a key input than others,” Turk said. “There’s a benefit and a difference between the price right now that we pay in the U.S. versus others internationally.”

Meeting matters: The U.S. is the world’s top exporter of LNG, an affordable, plentiful energy source that’s in growing demand and is much cleaner than traditional forms of coal-powered energy—especially in Europe, where LNG has been critical in keeping allied countries from seeking Russian energy sources. For NAM board members to be able to confront Biden administration officials on energy policy directly is a huge win for LNG producers and for manufacturers overall.

“We have more dialogue, more discussion, more interaction with members of the Biden administration than any administration that I’ve been involved in with the NAM,” Timmons said. “Where we have differing opinions, we do get feedback”—and, in the case of the meeting in Phoenix, we provide it.

Trend of the Week: Building Resilience

Some disruptions—like global pandemics—are just too unexpected to anticipate. As manufacturers consider the unknowns they may face in the years ahead, they are prioritizing general resilience instead of attempting to plan for everything. Here’s what you should know about this major trend in 2024.

What manufacturers should do: Manufacturers should focus on these four areas to increase their resilience, according to the NAM’s experts:

- Enhance cybersecurity to guard against new and emerging cyberthreats.

- View resilience as a necessary tool to protect business amid economic uncertainty.

- Shift leadership strategies to build a strong plan for future success, including establishing a path for development and cultivation of future leaders.

- Plan for more and as-yet-unknown disruptions in the future.

Expert opinion: Mike Lipinski, cybersecurity partner at Plante Moran, advises manufacturers concerned about the rising threat of ransomware. He points out how the dangers have evolved in recent years:

- “Manufacturing businesses that fall prey to ransomware can be attacked multiple times. Adversaries who breach your system sell other cybercriminals information about how they got in. The risk isn’t only data theft and access to information but also the criminals’ ability to create backdoors into your environment.”

Resources for you: Check out these NAM resources that can help companies bolster their resilience:

- Here is a useful guide that can guide you through dealing with disasters.

- Check out the NAM Shipping & Logistics program, which can help you cope with delays in shipments and funds in case the unexpected happens.

- If you’re facing legal issues, the NAM’s Legal Referral Service, powered by Meritas, can connect you to world-class legal talent in every sector of law.

Read the full 2024 trends report here.

Biden Touts Accomplishments, but Misses the Mark Elsewhere

In his State of the Union address Thursday, President Biden rightly celebrated manufacturing’s accomplishments—but he “missed the mark in several key areas,” according to NAM President and CEO Jay Timmons.

What happened: President Biden has reason to be proud when it comes to certain manufacturing-critical pieces of legislation, Timmons said, and the president touched on these in his speech.

- “On my watch, federal projects like helping to build American roads, bridges and highways will be made … creating good-paying American jobs,” President Biden told the audience, referring to the NAM-supported Bipartisan Infrastructure Law. And “[t]hanks to my CHIPS and Science Act, the United States is investing more in research and development than ever before.”

- The NAM has been a vocal supporter of CHIPS, which has supported large and small businesses all along the supply chain through an infusion of funds to boost much-needed domestic semiconductor production.

- And the president stood strong with the people of Ukraine and in defense of democracy, two areas in which the NAM has been consistent and unwavering in its own support. “Overseas, Putin of Russia is on the march, invading Ukraine and sowing chaos throughout Europe and beyond. … But Ukraine can stop Putin if we stand with Ukraine and provide the weapons it needs to defend itself. That is all Ukraine is asking.”

No new taxes: But the president also laid out some wrongheaded plans for America, manufacturers and the economy, the NAM said, such as his push to raise taxes on manufacturers.

- “If the cost of manufacturing in America is driven up by his agencies’ continued regulatory onslaught and a successful push to raise taxes, investment will be driven overseas and Americans will be driven out of work,” said Timmons, who appeared on Bloomberg’s “Balance of Power” ahead of the speech to discuss manufacturing priorities.

Protect U.S. innovation, competitiveness: In addition, the Biden administration’s push to invoke so-called “march-in” rights—which would allow it to seize the patents of any innovations it deems too highly priced in the event those patents had been developed in any part with federal money—would “rob Americans and the world of future cures and chill research into new breakthroughs across the manufacturing industry,” Timmons continued.

- “And if President Biden continues to heap blame on pharmaceutical manufacturers, rather than reining in pharmacy benefit managers with cost-saving reforms, Americans and their employers will continue to endure rising health care costs.”

What should happen: The president and manufacturers in America “share a profound commitment to democracy and to the values that have made America exceptional,” Timmons went on.

- A surefire way to restore faith in the democratic system is for Democrats and Republicans to prove it still works—“by delivering smart policies for the American people and by bolstering the industry that is the backbone of our economy and improves lives for all.”

How Close Is the Smart Factory of the Future?

Manufacturing is marching toward a future that is highly automated, intelligent and flexible.

Increasingly, smart factories are made up of connected machines that generate large amounts of data. This opens the door for artificial intelligence–driven analysis and new opportunities for insights on improving supply chains, processes, the customer experience, product quality and more.

But realizing this transformation can be difficult. Not all manufacturers have the resources, capital or talent required for a smart factory future. How are companies progressing on this journey, and what challenges stand in the way? To find out, the Manufacturing Leadership Council—the NAM’s digital transformation arm—conducted its Smart Factories and Digital Production survey.

Manufacturers are committed to M4.0: When it comes to digital technology, manufacturers are spending at a steady—and in some cases growing—basis.

- Nearly 69% of survey respondents said their M4.0 investments this year would continue unchanged from last year.

- Nearly 19% said they would increase investments, while just 10% said their investments would likely decline.

- Some 58% assessed their company’s digital maturity level in manufacturing operations at three to five on a scale of 10, suggesting the industry has moved beyond the initial stages of M4.0 and has reached an early majority of digital-model adoption.

How widespread are digital factories? Only about 7% of manufacturers say they have digitized their factory operations extensively.

- Approximately 15% expect to have their manufacturing operations digitized end-to-end by 2026.

- About 5% say their factories are already “very smart.”

- Approximately 53% say their factories and plants are getting smarter but are still works in progress.

In the future, will factories run themselves? While some manufacturers foresee a future of “lights out” factories, or those that mostly run themselves, most don’t think they will ever reach that state.

- About 49% of respondents expect fully or partially autonomous factories in the future.

- Some 40% say AI will be either very significant or somewhat significant in the years to come.

- Approximately 56% cite organizational resistance to change as the top barrier to implementing a smart factory.

For more details on these findings and the impact of smart factories as a whole, read the survey report: Smart Factories Are Still a Work in Progress.

SEC Finalizes Scaled-Back Climate Rule

The Securities and Exchange Commission has approved new climate disclosure requirements that have been in the works for the past two years. Changes made to the rule represent progress for manufacturers—though the industry will still face new cost burdens, the NAM said Wednesday night.

What’s going on: The SEC voted Wednesday in favor of requiring public companies to disclose greenhouse gas emissions and other climate-related information. Thanks in part to ongoing NAM advocacy—which Law360 (subscription) covered this week—the agency dropped its onerous, unworkable Scope 3 emissions mandate.

- That provision would have forced public companies to divulge information about emissions coming from anywhere in their supply chains—including from small and family-owned businesses.

Heeding the NAM: “The NAM demonstrated for the SEC the practical realities of such a sweeping proposed rule, encouraging the SEC to make significant changes to remove inflexible and infeasible mandates, require disclosure only of material information and protect small manufacturers from the impact of these requirements,” NAM President and CEO Jay Timmons said following the vote.

Key changes: In addition to the Scope 3 change, the SEC exempted smaller public companies from Scope 1 and Scope 2 emissions reporting and delayed the rule’s effective dates. The final rule also is more narrowly focused on so-called “material” information (data investors need to make informed decisions) than what had been proposed previously.

Keeping a close watch: The final rule “remains imperfect,” Timmons continued. “[A]nd it remains to be seen whether the rule in its entirety is workable for manufacturers.”

- “The NAM remains committed to ensuring the SEC acts within its statutory authority, prioritizes flexibility and provides much-needed guidance—just as we are committed to providing leadership in addressing environmental challenges. This is why the NAM is keeping all options on the table as we evaluate the rule’s potential impacts on the manufacturing sector.”

NAM, Allies File Suit Against EPA Over Air Standard

The NAM and seven association partners have filed suit against the Environmental Protection Agency to challenge the office’s overly stringent, recently finalized rule on particulate matter, or PM2.5, the NAM said Wednesday.

What’s going on: The eight groups filed suit in the D.C. Circuit to push back on the EPA’s National Ambient Air Quality Standards rule, which last month it lowered from 12 micrograms per cubic meter of air to 9, a 25% reduction and a stifling burden on manufacturers, the NAM said.

- “In pursuing this discretionary reconsideration rule, the EPA should have considered the tremendous costs and burdens of a lower PM2.5 standard,” said NAM Chief Legal Officer Linda Kelly. “Instead, by plowing ahead with a new standard, the agency not only departs significantly from the traditional NAAQS process, but also gravely undermines the Biden administration’s manufacturing agenda—stifling manufacturing investment, infrastructure development and job creation in communities across the country.”

- Participating in the suit with the NAM—which has repeatedly urged the EPA against overtightening the standard—are the American Chemistry Council, the American Forest & Paper Association, the American Petroleum Institute, the American Wood Council, the U.S. Chamber of Commerce, the National Mining Association and the Portland Cement Association.

Why it’s important: If it’s enacted, the stricter PM2.5 standard would cost businesses and the U.S. economy huge sums, hampering company operations and job growth and forcing tough choices on states and towns nationwide.

- The total cost of complying with the new acceptable concentration level could be as much as $1.8 billion, according to the EPA’s own estimates—and that number could go up.

- What’s more, it would make the U.S. less competitive globally. “Europe’s current PM standard is 25; China’s is 35,” NAM Managing Vice President of Policy Chris Netram told the House Energy and Commerce Subcommittee on Environment, Manufacturing and Critical Materials last month. “If we want the next manufacturing dollar to be spent in America rather than abroad, a standard of 9 is simply not feasible.”

NAM in the news: The New York Times (subscription) covered the lawsuit.

Previewing the State of the Union

With President Biden set to deliver the State of the Union address Thursday, manufacturing is likely to be in the spotlight once again. At the NAM, we will be listening closely for our key priorities—those that have been achieved and those still in progress.

Promises kept: President Biden has been a partner on a range of issues that are key to manufacturers across the United States. We hope he will outline how pro-growth legislation has helped set the stage for manufacturing growth, with industry employment reaching a 15-year high.

- CHIPS Act: The CHIPS and Science Act marked a major push to boost manufacturers’ competitiveness, supporting large and small businesses up and down the supply chain by investing in domestic semiconductor production and funding programs to support the STEM workforce, advanced technology development, excavation of critical minerals, clean energy and more.

- Bipartisan Infrastructure Bill: President Biden secured a bipartisan $1.2 trillion infrastructure bill, a long-sought, major achievement for manufacturers throughout the country, offering transformational upgrades and significant investments in America’s manufacturing capabilities.

- Inflation Reduction Act: Some of the provisions in the Inflation Reduction Act supported manufacturers across the United States, with direct investments and tax credits generating a major increase in manufacturing construction and jobs.

- Ukraine: The Biden administration has been unwavering in its support of Ukraine. The NAM—which in March 2022 passed a unanimous resolution denouncing Russia’s invasion of the country—has kept the pressure on Congress to pass the stalled Ukraine aid bill.

Progress to come: But this progress will be undermined if the Biden administration continues to issue onerous regulations and call for policies that make it harder to innovate, invest and expand in America. The NAM is working hard to push back against items that would harm manufacturers and encourage the president to refrain from pursuing policies that will make us less competitive.

- Taxes: The NAM is pushing back against any new taxes or attempts to increase tax rates on manufacturers, and we are pressing for tax policies that will make it easier to invest in the future—including the “tax trifecta” found in the recently House-passed Tax Relief for American Families and Workers Act. The NAM urges the Senate to approve these business tax provisions quickly.

- Protecting intellectual property: Late last year the administration proposed invoking “march-in” rights to seize the patents of any products it deems too costly—if those innovations were developed in any part with federal dollars. This move, which would open the door to similar actions in other sectors of manufacturing, would undermine manufacturers’ IP rights, disincentivize early-stage entrepreneurship and dissuade capital investment, all of which could jeopardize our ability to develop future cures. This is just one example of how actions that undermine manufacturers’ IP can have dangerous unintended consequences.

- Regulations: Burdensome rules—such as the tighter National Ambient Air Quality Standards from the Environmental Protection Agency and the Department of Energy’s recent freeze of liquefied natural gas export permits—are preventing manufacturers from creating jobs and harming U.S. competitiveness. We need to end the regulatory onslaught and give manufacturers the chance to grow.

- Energy: Manufacturers in America are at the forefront of the planet’s work to reduce emissions and promote sustainable energy. But to be effective, we need to embrace an all-of-the-above energy strategy that uses the fuel we have while developing the tools we need.

- Immigration: Immigration and border security reforms must be a priority for the administration and Congress. Inaction poses significant economic risks—especially at a time when manufacturers have 600,000 open jobs. Manufacturers are leading on bipartisan solutions, like those found in our A Way Forward plan.

The last word: “Our commitment is to work with anyone, and I truly mean anyone, who will put policy—policy that supports people—ahead of politics, personality or process,” said NAM President and CEO Jay Timmons. “Because here’s what I know: Manufacturers are building an incredible future for our country and our world. And we need partners in the federal government who will work with us to reduce burdens on manufacturers and manufacturing workers, rather than creating barriers to our success.”

Learn more: For more information on the state of manufacturing, check out the 2024 NAM State of Manufacturing Address here.

Previewing the SEC’s Climate Rule

For the past two years, the U.S. Securities and Exchange Commission has been considering a rule that would require businesses to report huge amounts of information about companies’ climate-related risks, strategies and impacts. As the SEC prepares to release its final version of the rule this Wednesday, we spoke with NAM Vice President of Domestic Policy Charles Crain about what manufacturers should expect.

The background: In March 2022, the SEC proposed what the NAM has called an overreaching, unworkable and burdensome climate disclosure rule. According to Crain, the initial proposal would have required extensive disclosures as well as invasive tracking procedures to gauge climate impact and emissions throughout companies’ supply chains—significantly increasing costs and liability for manufacturers.

- “The proposal would have had major implications for the entire manufacturing sector, including both large and small public companies—and even privately held businesses throughout manufacturing supply chains,” said Crain. “As proposed, the rule represents a significant threat to manufacturing competitiveness.”

The pushback: In the two years since the rule was first proposed, the NAM has pressed for significant changes—in detailed letters to the SEC, in congressional testimony and in meetings with SEC commissioners and staff.

- “Manufacturers have made it a top priority over the past two years to convince the SEC that they need to change their approach,” said Crain. “The NAM has spent significant time and effort explaining to the SEC why its proposal was unworkable and likely unlawful and illustrating the impact of the rule’s overwhelming cost burden on manufacturers.”

- “But we also offered specific and actionable suggestions to help the agency tailor the rule, make it more workable to manufacturers and bring it back within the SEC’s statutory authority.”

The preview: With the SEC set to publish its final rule tomorrow, Crain says the NAM is keeping an eye on key inflection points, including the following:

- Scope 3 emissions reporting: The proposal’s Scope 3 mandate would require public companies to disclose the emissions of their supply chain partners—including small and family-owned businesses. If Scope 3 is curtailed or absent, that would represent significant progress for manufacturers.

- Financial statement reporting requirements: The NAM will be tracking the degree to which companies are required to incorporate climate information into their financial statements. The NAM called the proposal’s approach to financial statement reporting “unworkable [and] highly burdensome.”

- Materiality: The SEC is only allowed by law to require “material” disclosures—i.e., financial information that allows investors to make informed decisions. Mandates in the final rule that require immaterial disclosures or seek to redefine materiality could exceed the SEC’s legal authority.

- Implementation: The NAM will consider when and how the rule takes effect, and whether the SEC has provided scaled requirements for smaller companies or tailored implementation plans for certain provisions within the rule.

- Small-business impact: The proposal would have harmed small and privately held businesses disproportionately. The SEC must do a better job at protecting these companies in the final rule.

The expectation: Crain says the NAM’s advocacy appears to have made a difference.

- “Recent news reports suggested that some provisions in the rule may have been modified in alignment with the NAM’s suggested changes,” said Crain. “But it remains to be seen whether the final rule, taken as a whole, is actually workable for manufacturers.”

The next step: The NAM’s next moves will depend on the specifics of the final rule—but the conversation is unlikely to end there.

- “The NAM has been clear that a failure to bring the rule back within the agency’s statutory authority could invite legal action. On the other hand, a balanced, workable rule could obviate the need for litigation,” said Crain.

- “Regardless of the exact content of the rule, the NAM is committed to providing resources to our members to help companies understand and comply with any new requirements. We will also continue to engage with the SEC and Congress to address any implementation issues, seek guidance on any unclear provisions and, if necessary, push for changes to the final rule.”

- “As we have for the past two years, the NAM will continue to advocate on manufacturers’ behalf.”

Trend of the Week: Process Innovation

Amid an uncertain economy, manufacturers will have to reinvent and upgrade their processes, from training employees to organizing supply chains and more. For today’s manufacturing trend of 2024, we’re looking at manufacturers’ efforts to improve their processes across their operations.

What manufacturers should do: Manufacturers looking to guard against economic upheaval should consider these steps, according to NAM experts:

- Consider improvements to techniques, tools, software, technologies and behaviors.

- Streamline customer service and the way products are sold to customers.

- Optimize the supply chain with help from partners, automation and design improvements.

- Reinvent processes to realize benefits (e.g., speed time to market, cut costs, work around supply challenges).

Expert opinion: Manufacturers are investing heavily in innovation, even as budgets have become tighter, according to EY Americas Industrial Products Sector Leader Brian M. Legan.

- As he points out, “Nearly half (49%) of manufacturing CEOs who participated in the EY CEO Outlook Survey plan on accelerating or maintaining current levels of innovation investment and portfolio transformation.”

- Meanwhile, “more than half of these CEOs (56%) also indicated that the main source of financing for these investments will be from savings generated from business performance improvements.”

Resources for you: Check out these NAM resources to learn more about manufacturers’ process improvements:

- The Innovation Research Interchange is an NAM division devoted to studying the next wave of manufacturing innovation and providing manufacturers with the resources they need to benefit from it.

- You can also get an inside look at process innovation by attending the Manufacturing Leadership Council’s plant tours. (The MLC is the NAM’s digital transformation division.)

Read the full 2024 trends report here.