Ketchie’s Courtney Silver Chosen to Lead NAM’s Small and Medium Manufacturers Group

Click Bond’s Karl Hutter to Serve as Vice Chair

Washington, D.C. – The National Association of Manufacturers today announced that Ketchie Inc. President and Owner Courtney Silver will serve as chair of the NAM’s Small and Medium Manufacturers Group and Click Bond President and CEO Karl Hutter will be vice chair. Silver and Hutter will work under the continued board leadership of NAM Board Chair and Dow Inc. Chairman and CEO Jim Fitterling and NAM Board Vice Chair and Johnson & Johnson Executive Vice President and Chief Technical Operations and Risk Officer Kathy Wengel.

“Small and medium-sized manufacturers are at the heart of our economy and represent 90% of the NAM’s membership. Our country’s success is tied directly to their success, and with Courtney and Karl as leading manufacturing voices, we are well-positioned for 2023,” said NAM President and CEO Jay Timmons. “No matter what challenges we face, our association and industry remain steadfastly committed to policies that uphold the values that have made America exceptional and keep manufacturing strong: free enterprise, competitiveness, individual liberty and equal opportunity.”

“It is a privilege to serve our industry as chair of the SMM Group at the NAM. With so many critical policy issues facing members this year, we will continue to lead the charge in Washington and across the country,” said Silver. “We’re all dealing with pressures from regulatory overreach, tax code uncertainty, the workforce crisis and more. I look forward to working with the team at the NAM to advance policies that support innovation and growth and enhance our competitiveness—and to collaborating with other small and medium-sized manufacturers, including family-owned businesses like mine, to fix these make-or-break policies central to our survival.”

“I am honored to be chosen to lead the SMM Group at the NAM as vice chair,” said Hutter. “From educating elected leaders on the policies needed to empower the nearly 13 million people employed in manufacturing, to helping companies tap into the NAM’s wealth of operational resources, I look forward to working closely alongside the NAM’s leadership to support small and medium-sized manufacturers in growing their companies and our economy.”

The NAM Board of Directors guides the association’s leadership in policy advocacy, legal action, operational excellence, workforce development and news and insights. More than 200 manufacturing leaders serve on the NAM Board, helping the industry advance an agenda that promotes growth and prosperity for all Americans.

The new board leadership was elected at the September meeting of the NAM Board of Directors.

Silver previously served as vice chair of the NAM’s SMM Group. As president and owner of Ketchie, she leads a woman-owned, third-generation North Carolina manufacturer. She has worked at Ketchie for more than 14 years. She is a past recipient of the Manufacturing Institute’s STEP Ahead Award (now the Women MAKE Award), which recognizes manufacturing women who exemplify leadership within their companies as well as their communities.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.9 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers: Legislation Is a Bold, Important Step Toward Ramping Up the Domestic Manufacturing of Essential Inputs

Timmons: Every manufacturer will benefit. But there is more to be done.

Washington, D.C. – Following the House’s passage of the CHIPS-Plus Act, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“This legislation is a bold, important step toward ramping up the domestic manufacturing of essential inputs used by virtually every part of our industry. Every vote for the CHIPS-Plus Act was a vote for a more competitive manufacturing industry in America. This bipartisan legislation shows that Congress is taking the problems of supply chain disruptions and inflation seriously. Every manufacturer will benefit. But there is more to be done.

“Once President Biden signs it into law, manufacturers will work with lawmakers to build on the momentum and continue our advocacy for important measures that did not make it into the final CHIPS-Plus legislation, including trade measures, anti-counterfeiting protections and other workforce development priorities.

“But if lawmakers are truly serious about competing with China, they will now oppose the tax increases and attacks on pharmaceutical innovation in the latest reconciliation bill proposal, which will certainly lead to continued inflationary pressures. Congress should stay focused on bipartisan solutions, not legislation that weakens our economy and makes us less competitive with other countries.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org

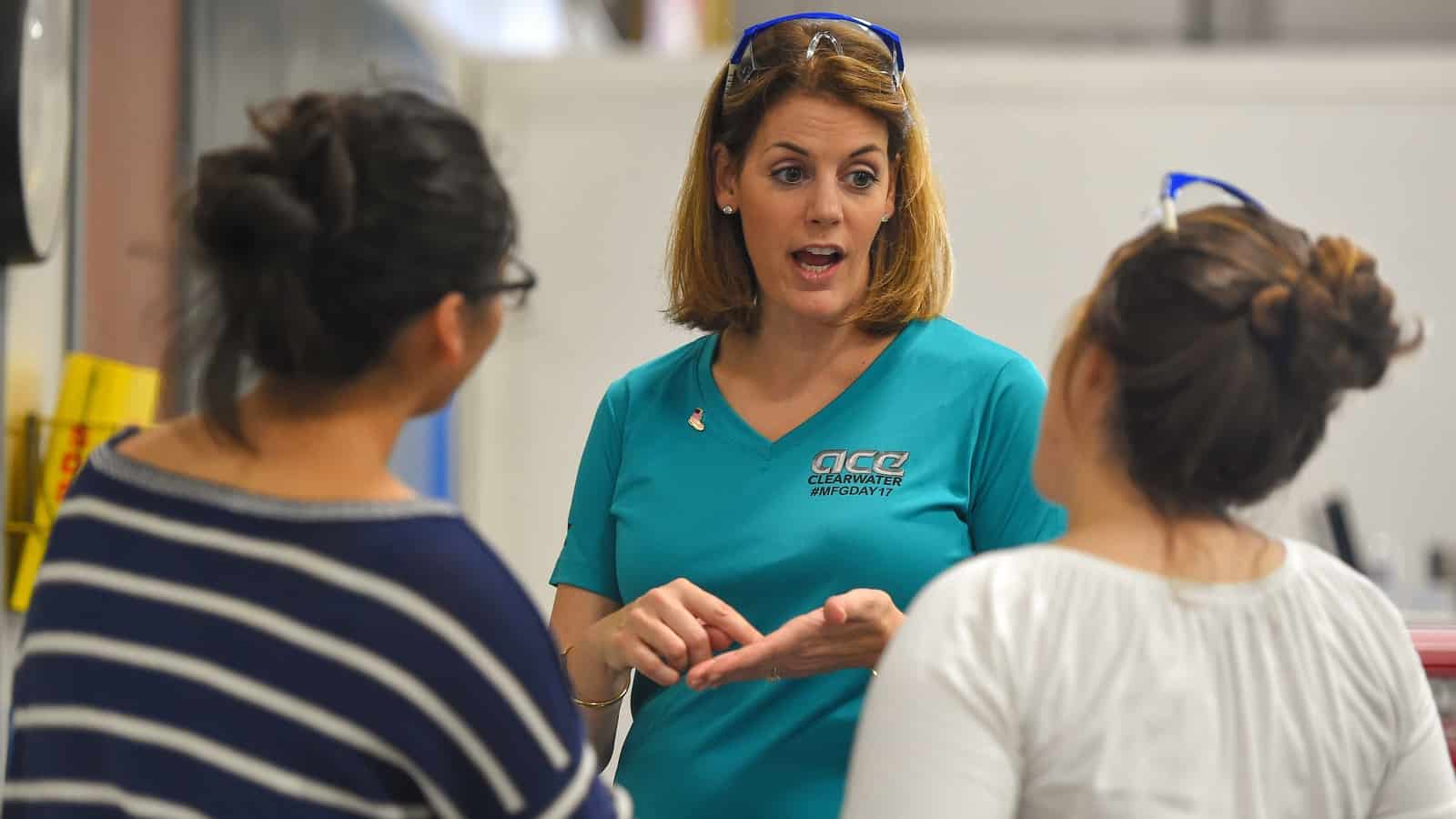

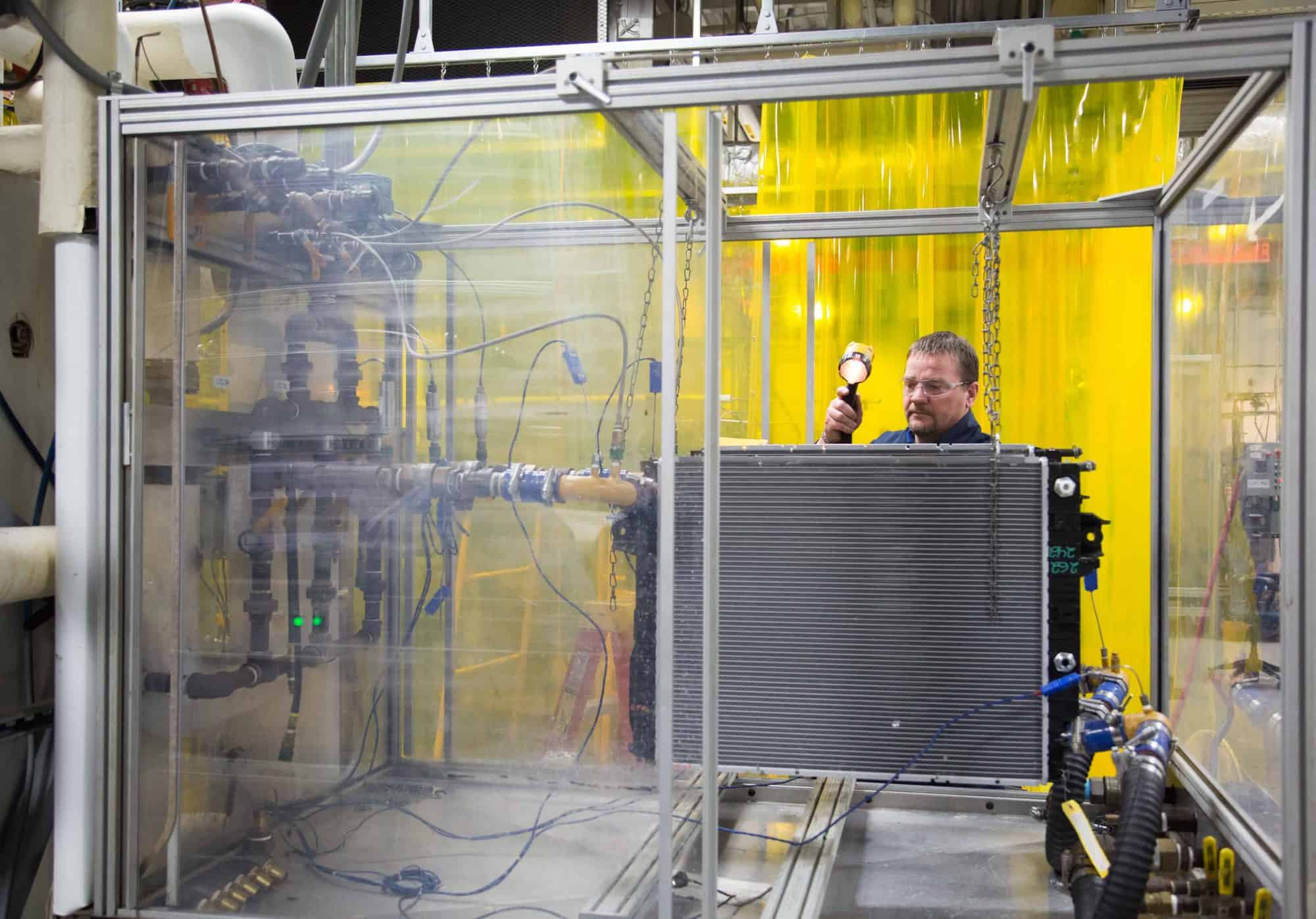

MFG Day Inspires Future Creators to Explore Manufacturing

Every year, shop floors across the country open their doors to students, parents, teachers and community leaders to showcase modern manufacturing careers through MFG Day. Carolyn Lee is the Executive Director of The Manufacturing Institute, the workforce and education partner of the National Association of Manufacturers. Here she shares what MFG Day is, why it is so important to the future of the industry and how manufacturers can drive attendance to their MFG events.

What is MFG Day?

MFG Day is an initiative to raise awareness for the many opportunities in modern manufacturing. On MFG Day, manufacturers open their doors to open minds about well-paying, rewarding and productive careers that give the next generation the chance to create the future using tomorrow’s technologies today.

When does it take place?

MFG Day begins on the first Friday of October but events extend throughout the month. Last year there were more than 3,000 MFG Day events hosted in 49 states as well as in Canada and Mexico. More than 325,000 students participated in MFG Day events.

What happens at MFG Day events?

Participants get a chance to see what is really taking place on many shop floors. This isn’t your grandparents’ manufacturing industry. Artificial intelligence, 3D printing, and co-bots—robots that work alongside humans—are commonplace on shop floors. And augmented reality and virtual reality are now just reality for many modern manufacturers. All of this and more is available to those who attend an on-site or virtual MFG Day event.

Why is MFG Day especially important this year?

This is a critical moment for the manufacturing industry. The U.S. economy as a whole is facing an unprecedented challenge in response to the COVID-19 pandemic. Manufacturing is no exception, but the industry’s leadership in our nation’s response is showing the public how critical manufacturing is to our country. Manufacturers, the men and women who make things in America, are the ones making the test kits, personal protective equipment and daily items Americans need right now during this crisis. They are developing medicines and vaccines and the equipment needed to test and study treatments. Throughout our nation’s response effort—and during MFG Day in particular—we hope that more young people will see how creators respond when our country needs them most and choose to join in this effort by pursuing a career in modern manufacturing.

Do you have any advice for manufacturers who want to inspire more people to join the workforce?

Host a MFG Day event, and register it on CreatorsWanted.org, the new digital home for MFG Day, so people in your area can find it and attend! MFG Day is your opportunity to stand up and be counted, showcasing the reality of careers in our industry. Our country’s future is tied to the continued success of the manufacturing industry, and manufacturing’s success will be determined, as it always has, by its next generation of leaders. Join us in this critical effort to strengthen our industry into the future.

Manufacturers Fight COVID-19 But Face Legal Obstacles

As COVID-19 affects communities nationwide, manufacturers are taking extraordinary steps to supply the products, including daily essentials and medical supplies, that Americans need. Unfortunately, outdated liability rules might expose these same manufacturers to litigation, creating added risk as they go above and beyond for the COVID-19 response. National Association of Manufacturers General Counsel Linda Kelly explains.

What’s the problem manufacturers face?

Our country needs manufacturers to produce food and critical goods so that most of us can shelter in place and slow the virus’ spread. Our sector has also stepped up in an unprecedented way. For example, NAM members have started to produce masks, gowns and other equipment for use on the front lines, and they didn’t wait around until they had perfect legal certainty before they acted to do the right thing. Some of our members have donated the equipment that they would use to local hospitals.

Unfortunately, even as manufacturers are making sacrifices and performing essential services, unprecedented regulatory uncertainty and rapid changes in the rules make it hard to know what actions could expose manufacturers to unfair litigation. Manufacturers always put the health and wellbeing of employees and families first. So manufacturers are stuck: they’re committed to doing the right thing, but they could also face lawsuits as a result.

What do manufacturers need to solve this problem?

America’s manufacturers need sensible liability protections for the workplace so our essential workers can continue to combat COVID-19 and help the nation move toward recovery. In an unprecedented time of national need, America’s manufacturers have stepped up to aid those on the front lines with essential equipment and materials and to maintain our way of life. And our elected officials should protect those who, without being asked, did the right thing.

What should those protections look like?

The NAM has developed a list of proposed reforms: commonsense adjustments to help ensure we have enough food on the table, equipment for our hospitals and eventually vaccines and life-saving drugs for our world.

We need protections for the workplace so critical manufacturers can continue to operate. We need to extend Good Samaritan protections to cover those who donate equipment, or who may be producing protective gear or even ventilators and more complicated medical equipment for the first time. We need to bar suits for public nuisance against critical manufacturers, as well as shareholder suits that try to “Monday-morning quarterback” decisions manufacturers have to make every day in the face of tremendous regulatory uncertainty.

Who should these reforms apply to?

These are specific, narrow reforms. They should be limited to critical businesses that operate to serve our country during the crisis, and they should apply only during the emergency and for a “wind-down” period after the declared emergency ends. We need reforms that prevent abuse of our legal system, while at the same time holding any actual bad actors accountable.

This is an unprecedented situation—and we need regulatory certainty that meets the moment.

See the NAM’s pandemic liability policy recommendations.

CARES Act Offers Support for Manufacturers Affected by COVID-19

On March 27, 2020, President Trump signed the Coronavirus Aid, Relief and Economic Security Act, or CARES Act. National Association of Manufacturers Director of Tax and Domestic Economic Policy Charles Crain explains its significance.

What is the CARES Act?

The CARES Act is essentially a rescue vehicle for the economy. It’s not a long-term stimulus package, but rather a short-term emergency spending package to provide a specific injection of funds right now.

We’re facing a dramatic economic slowdown. Businesses don’t have the capital they need to operate because there’s not a lot of commerce going on. People are staying safe, staying inside and spending less money than they ordinarily would, and that has an impact on the economy generally and businesses specifically. The CARES Act is designed to provide capital for businesses and capital for families to weather the crisis.

How does the CARES Act help?

It does a number of different things. Because of the NAM’s leadership and advocacy, the CARES Act includes many of manufacturers’ priorities—priorities we first outlined in the NAM’s “COVID-19 Policy Action Plan Recommendations.”

First, the CARES Act offers almost $350 billion in loans to small businesses. The Small Business Administration Paycheck Protection Program provides loans up to $10 million, and as long as the loans are used to keep employees on payroll or on certain overhead costs like rent, mortgage interest or utilities, that loan will be forgiven.

Second, the CARES Act helps companies keep their employees, both through the PPP and through the Employee Retention Tax Credit, which allows eligible businesses that don’t use the PPP for payroll to claim a tax credit.

Third, the CARES Act allows for businesses to defer employer payroll taxes from March 27 until the end of this year, with half of it due at the end of 2021 and the other half at the end of 2022.

Fourth, it temporarily increases allowable interest deductions from 30% to 50% for 2019 and 2020, helping to provide critical liquidity for businesses.

Fifth, it sends money directly to American families in the form of relief checks up to $1,200 per qualifying individual and up to $500 per child, which helps employees and business owners alike.

How can manufacturers access the programs they need?

There’s a wide range of agencies involved in this effort and many are operating on different timelines. The Paycheck Protection Program, for example, has already begun—eligible businesses can now apply for loans directly with their local lender. For our members, the NAM provides important deadlines and points of access, as we have done with information about loans and tax provisions so far.

Where can manufacturers get more information?

The NAM regularly updates COVID-19 resources for manufacturers. Helpful links for small businesses are also available.

Manufacturers Make Cybersecurity Central to Industry Culture

As rapid technological innovation sweeps across the manufacturing industry, cybersecurity has become a top priority. David Brousell, Vice President and Executive Director of the Manufacturing Leadership Council—the world’s first member-driven, global business leadership network dedicated to senior executives in the manufacturing industry—explains the importance of cybersecurity and what manufacturers are doing to combat global threats in the digital age.

Why is cybersecurity important for modern manufacturing?

Manufacturers are using cutting-edge digital technology to a greater degree than ever before. We’re putting sensors in equipment, digitizing supply chains and gathering data from customers to better the customer experience, to name just a few examples. The number of electronic connections we’re making is enormous—and the more you electronically link products and processes, the more vulnerable they become to cyberattacks.

What are the impacts of cyberattacks?

When we talk about cybersecurity, we’re not just talking about people trying to steal intellectual property. We’re also talking about attacks that target business operations, which can actually bring business to a halt. Manufacturers need to be able to guard against these attacks across the board in order to do their own innovative, cutting-edge work and to deliver for customers in the United States and around the world. That’s why manufacturers must invest in developing solutions that can stand strong against even the most sophisticated assault.

What are some of the challenges manufacturers face in cybersecurity?

The number one challenge is the increase in attacks. We do a lot of survey work among manufacturers of the Manufacturing Leadership Council, and the overwhelming majority of survey participants say they’re expecting more attacks in the year ahead. Just keeping up with the sheer volume of attacks is a big issue for manufacturing companies—large and small alike. This isn’t just an issue for multibillion-dollar enterprises. Cybersecurity is everyone’s concern.

What are manufacturers doing in the cybersecurity space to keep their work secure?

We’re taking a variety of actions. We’re continuing to invest in technology. We’re training people to understand best behaviors and best practices. And we’re trying to protect more and more on a systems level. For example, some companies are housing their information in the cloud because they feel that there are greater protections in a cloud environment than in a system on their own premises.

Most importantly, though, companies are adopting cybersecurity as a cultural discipline and making cybersecurity part of their business’ DNA and culture. Over many decades, manufacturers have made physical safety a well-honed science. Now we have to raise cybersecurity up to that level of safety if we’re going to bring it under control. We talk about how safety is everybody’s business—and now cybersecurity has to become everybody’s business, too.

What a Yield Curve Inversion Means for the Economy

Last Wednesday, as yields on shorter-term bonds surpassed those of longer-term bonds, the U.S. economy briefly experienced an “inverted yield curve”. Historically, such an inversion has been a reliable predictor of recessions to come.

Chad Moutray, chief economist for the National Association of Manufacturers, explains the significance of the yield curve and whether manufacturers should worry that a recession is on the way.

What is a yield curve?

In its simplest terms, if I lend money to you over several years, I would expect to get receive a higher interest rate to compensate me for giving up access to my money for a longer time frame. In a healthy economy, interest rates should be upward-sloping as the length of maturities increases.

What does it mean if a yield curve inverts?

An inverted yield curve means that the interest rate for short-term loans is higher than for longer maturities. This would imply that financial markets might be more pessimistic in its outlook.

An inverted yield curve can foreshadow a recession. The spread between 10-year and 2-year Treasury bonds is often seen as an important barometer. Since World War II, when this yield curve has inverted, the U.S. economy has entered a recession within the following 12 to 18 months.

The yield curve between 10-year and 2-year Treasury yields inverted last week. It’s positive now, but still close to inversion. The last time this spread inverted was June 2007, predating the start of the Great Recession by five months.

Should manufacturers be worried? Does that mean that a recession is just around the corner?

There are warning signs that we are closely following. Broadly, the global economy is clearly slowing, as noted in our most recent monthly report, and financial markets have been highly volatile in recent weeks, exacerbated by trade uncertainties. As a result, businesses in the U.S. have become more hesitant in their spending and there are worries that the economic slowdown abroad could find its way to the U.S. Within the manufacturing industry, production is contracting both in the U.S. and abroad, and hiring has slowed in the sector.

However, a yield curve inversion does not necessarily mean that a recession is imminent. Yields may be influenced by other factors, and there are positive economic signs too. Consumer spending remains strong, and the labor market remains near 50-year lows. The U.S. economy should also grow 2.3 percent in 2019.

What can policymakers do to avoid an economic downturn?

Central banks around the world are easing monetary policies to stimulate growth, or to provide an “insurance policy” for the economy so economic recovery can be sustained. These trends have pushed 10-year Treasury yields to their lowest levels since October 2016.

Manufacturers remain optimistic about the future, but in order to keep growing, we need to address the workforce crisis and resolve trade uncertainties. Namely, passing the USMCA, reauthorizing the Ex-Im Bank and securing a bilateral trade agreement with China are necessary to ensure manufacturers in the U.S. can continue to grow.

Importing Prescription Drugs from Canada is a Serious Safety Risk

The Trump administration wants to allow Americans to import drugs from Canada as part of the President’s larger goal to lower prescription drug prices.

Robyn Boerstling, Vice President of Infrastructure, Innovation and Human Resources at the National Association of Manufacturers, explains the proposal and how drug importation affects manufacturers.

Why is drug importation coming up now?

This has been one of President Trump’s priorities since the 2016 campaign. More broadly, lowering prescription drug prices has been a top priority for manufacturers and policymakers for some time now, as health care costs continue to rise.

However, manufacturers in the U.S. think importing drugs from Canada poses a serious health risk, especially considering the counterfeit challenges we already face.

How does drug importation fit into the larger conversation on health care?

The NAM insists something must be done to address high health care costs. But it shouldn’t just be about the transaction at pharmacy counter. Any solution has to be holistic, addressing the systematic challenges without sacrificing competitiveness and free enterprise in the process.

How does drug importation affect manufacturers?

The biopharmaceutical industry has experienced tremendous growth recently, supporting 1,100 manufacturing plants across the U.S. and Puerto Rico and employing thousands of high-skilled employees. In fact, the biopharmaceutical industry was the top manufacturing sector for job postings in 2018, according to Burning Glass Technologies’ Labor Insights.

These companies are at the cutting edge of creating the cures of tomorrow, and America’s policies on drug prices should take into consideration both the desire to lower prescription drug prices and the opportunities and benefits provided by this sector. Moreover, other countries don’t guarantee the same standards as drugs made in the U.S—and we should not be looking outside our carefully managed supply chain as a source of our medicines.

Why is drug importation a threat for consumers?

Counterfeit and substandard drugs are a growing problem worldwide. The challenge is most acute in the developing world, impacting about 10 percent of the drug supply according to the World Health Organization. Fortunately, the U.S. has the safest drug distribution system in the world, but importing drugs from Canadian pharmacies would be a direct challenge to that proven model.

Would drug importation work in the United States?

If this plan led by the Trump administration is truly a way to lower costs, we have to ask: Are the savings guaranteed for the patient? The infrastructure that will be necessary to assure safety will be costly. It’s difficult to ignore the question, “Will importation actually reduce prescription drug expenditures?”

It’s worth noting, in 2004 when the Congressional Budget Office looked at this issue, significant long-term savings on prescription drug spending did not materialize, especially in a Canada-only importation scenario.

There is something broken when people have access to but cannot afford the drugs they need. If the United States can build the safest medical supply in the world, we can find ways to be more affordable to the people who need relief the most.

Manufacturers Adapt to Lead in an Increasingly Digital Age

"You can’t make this transition to the digital era by yourself. You need to be with other companies, to learn from them."

In September 2018, the National Association of Manufacturers acquired the Manufacturing Leadership Council, an association for manufacturing executives that is dedicated to helping the industry transition to the digital era. Nearly one year later, the MLC wraps up its 15th Anniversary Manufacturing Leadership Summit and continues to provide its members with programs and services around digitization.

MLC’s Co-Founder, Vice President and Executive Director David R. Brousell shares the groundbreaking work of the organization and why it matters to manufacturers today.

What is the Manufacturing Leadership Council?

The MLC is designed to help senior manufacturing executives and emerging leaders define and shape a better future for themselves, their organizations and the industry at large by focusing on the intersection of critical business and technology issues that will drive growth today and in the future. We do live events like conferences; we do plant tours that enable members to see firsthand how different companies are implementing the latest digital technologies; and we publish in-depth articles that focus on best practices and cutting-edge ideas on the use of technologies and the leadership requirements of the digital age.

How is leadership changing in the digital age?

It’s changing in some very important ways. There’s a whole new layer of competency that has to be added to the traditional functions of leadership. We call this “digital acumen,” which has to do with understanding the potential of advanced technologies like analytics, artificial intelligence, collaborative robotics, 3D printing and other technologies. It’s not just improving efficiencies, but also offering new business models, ways of doing things and services.

This new era in manufacturing requires leaders to manage organizations that are flatter and more collaborative, with more and more employees having the benefit of information at their fingertips. Managing in prior years was around a top-down structure. That doesn’t cut it in the digital age.

What benefit do companies get from being a part of this group?

The MLC presents the opportunity to be part of a community that is collectively sharing ideas, insights and best practices to as the industry continues its radical transition. The truth is, you can’t do this alone as a company. You can’t make this transition to the digital era by yourself. You need to be with other companies, to learn from them, to learn what’s possible, to see what works and what may not work well in your company and to form that bond. It’s a tremendous learning experience.

What does the future look like for manufacturing—and how does the Manufacturing Leadership Council fit in?

The future looks very, very bright for manufacturing. We’re going to increase efficiency and produce products that satisfy personalized needs—everything from cars to medicine. We’re going to be able to have better quality and create jobs that are fulfilling, exciting and intellectually stimulating. The extent of innovation happening right now in manufacturing is mind-blowing.

But this is not an easy transition. The future offers tremendous opportunities, but only if we make the transition industry-wide. If we’re able to do that, not only will individual companies be more successful globally, but the U.S. manufacturing industry as a whole will continue to lead the world. There’s a lot at stake for manufacturers. That’s why the partnership between the Manufacturing Leadership Council and the NAM is so important.

Why the Ex-Im Bank is Critical for Manufacturers

The Ex-Im Bank helps U.S. manufacturers compete for deals around the world.

In May, the U.S. Senate voted to confirm President Donald Trump’s nominees to the Export-Import Bank board. The board now has a quorum for the first time in four years, allowing it once again to consider deals larger than $10 million. Manufacturers’ attention now turns to securing congressional reauthorization of the Ex-Im Bank.

NAM President and CEO Jay Timmons explains what’s at stake.

The NAM is leading the fight for Ex-Im Bank reauthorization. Start with the basics. What does that mean?

Later this year, Congress will have to vote on whether to keep the Ex-Im Bank open and authorize it to continue helping manufacturers in the United States compete for deals around the world.

Why does the Ex-Im Bank matter so much to manufacturers?

It’s a vital tool to support manufacturing jobs in the United States. The Ex-Im Bank has supported 2.5 million jobs since 2000. Typically, more than 90 percent of the Ex-Im Bank’s transactions directly support small businesses.

And here’s something that’s really impressive — the Ex-Im Bank has generated $9.6 billion for taxpayers since 1992. It’s a government agency that makes money!

Other countries are running nearly 100 other export credit agencies. So, if we don’t have the Ex-Im Bank, we are at a big disadvantage.

You mention “export credit agencies.” You mean other countries have their own versions of the Ex-Im Bank?

Exactly. And they use those agencies to lure manufacturers to their countries, support their own manufacturers and steal manufacturing jobs away from the United States. That’s not going to change. So, we can “disarm” ourselves here in the United States and let other countries like China have the advantage. Or we can support the Ex-Im Bank.

So this all comes back to China?

Definitely. It helps level the playing field for manufacturers in the United States to compete with China, as well as other countries.

Two of China’s export credit agencies provided $45 billion in medium- and long-term investment support for projects around the world, more than the rest of the world combined. That’s what we have to compete against.

What can manufacturing workers or manufacturing supporters do to make a difference?

Contact your senators and representatives. Tell them to support the Ex-Im Bank and reauthorize it. Let them know that supporting the Ex-Im Bank is supporting American manufacturing workers.