Students Experience Manufacturing at MFG Day Kickoff

To say there was a lot for students to see and do at chemical manufacturer BASF’s MFG Day event at River Parishes Community College last Friday would be an understatement.

- The activities at the Gonzales, Louisiana, college were made possible by a partnership between with the school and the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate.

A rewarding experience: Hundreds of middle and high school students gathered on the campus for a chance to learn about manufacturing and how rewarding careers in the industry can be.

- Representatives from approximately 10 manufacturing companies and various departments at the college set up demonstration and interactivity stations where the students could find out more about the different careers and training programs available in their community.

- BASF was platinum sponsor of this year’s MFG Day, a flagship initiative of the Manufacturing Institute that introduces students, parents and educators to the manufacturing industry.

Hands-on activities: Students got the chance to conduct science experiments (including one in which they made putty and learned how different chemicals react to create the substance), simulate firefighting, experience virtual and augmented reality welding systems, try out process control simulators and more.

Readying the future workforce: Partnerships between academia and industry are helping to deliver the right workers to the right jobs, Louisiana Economic Development Secretary Don Pierson told the students and other audience members at the event.

- The LED’s “FastStart workforce development [program], that integrates with community colleges and four-year universities across our state, help[s] guide and then make the recipe to deliver exactly what BASF needs, exactly what Shell needs, exactly what ExxonMobil needs” in its workforces, Pierson said.

- Said A. Denise Graves, Ascension Public Schools assistant superintendent, “[Today] is an opportunity for our children because they’re going to go home and they’re going to share this information [about manufacturing careers], they’re going to share this day with others.”

A guiding path: Louisiana State Rep. Ken Brass, who is also an electrical engineer at BASF, described his journey into manufacturing.

- “I would like to publicly and personally thank BASF and the Manufacturing Institute for investing in me and my career,” he said. “It wasn’t too long ago [that] I was a senior at a nearby high school … and I was wondering [about] the path forward for my life after high school.”

- “I attended a STEM event which led me to attend Southern University and ultimately receive a bachelor’s degree in engineering with a minor in mathematics,” he continued. “Upon graduation, BASF took a chance on me. I have now been at the company for over 20 years, which has allowed me the opportunity to continue to live in my hometown of St. James and to work in a nearby parish.”

Changing perceptions: Activities such as those at BASF’s MFG Day event allow students to get a real taste of modern manufacturing and perhaps take career paths similar to Brass’s, MI Executive Director Carolyn Lee said.

- “MFG Day … is designed to give manufacturers a platform to come together to address one of the biggest challenges we all face each and every day—and that’s to change the perception of our careers,” Lee said.

- “We’re showing students what manufacturing really looks like today and how operators get to work … in clean, bright, sleek technology-driven facilities while accessing state-of-the-art equipment and tools, including robotics and augmented reality, drones and digital twins, just to name a few.”

A bright future: “We know that by building an interest in STEM careers today, we’ll create the sustainable solutions [we need] for tomorrow,” said BASF Senior Vice President and General Manager Jerry Lebold. “It’s through these kids and … efforts like this with RPCC that I know that future is going to be more sustainable and it’s going to be very bright.”

Creators Wanted and Union Pacific Dazzle the Twin Cities

Last week, Saint Paul College in St. Paul, Minnesota, which boasts a student body that is 65% people of color, became the 19th stop of 20 for the Creators Wanted Tour, a joint project of the NAM and the Manufacturing Institute, the workforce development and education affiliate of the NAM.

Over three days, with Union Pacific as the lead sponsor, the stop drew more than 600 visitors, from students to educators. Meanwhile, 42,000 online signups in Minnesota helped the campaign surpass 1.5 million nationwide from students and career mentors interested in modern manufacturing careers.

Twin Cities kickoff: Union Pacific Executive Vice President of Marketing and Sales Kenny Rocker gave the keynote address at the kickoff event, emphasizing the reward of manufacturing careers. He was joined by MI President and Executive Director Carolyn Lee, Saint Paul College President Dr. Dee Dee Peaslee, Minnesota Chamber of Commerce President and CEO Doug Loon and Trane Technologies Vice President of Product Management Dave Molin.

keynote address at the kickoff event, emphasizing the reward of manufacturing careers. He was joined by MI President and Executive Director Carolyn Lee, Saint Paul College President Dr. Dee Dee Peaslee, Minnesota Chamber of Commerce President and CEO Doug Loon and Trane Technologies Vice President of Product Management Dave Molin.

- “When I talk about opportunities, I’m talking about really good-paying jobs … At Union Pacific, we’re talking jobs that are … averaging over $100,000 a year, and that’s without benefits, and so you just really have an opportunity to make an impact from that perspective,” said Rocker.

- “At Trane Technologies, our vision is to boldly challenge what’s possible for a sustainable world,” added Molin. “It is the engine of our company, and we live it every day. And to do that, we need bright minds and the best minds in the world. We need diverse thinkers, we need creators, and our doors are open to everyone.”

- Notably, leaders from key government business and workforce partner organizations attended the kickoff, including the Minnesota State Advanced Manufacturing Center of Excellence, Minnesota Black Chamber of Commerce, Minnesota Parent Union and St. Paul Area Chamber, representatives from the offices of U.S. Reps. Brad Finstad (R-MN-1), Angie Craig (D-MN-2), Dean Phillips (D-MN-3), Betty McCollum (D-MN-4) and Michelle Fischbach (R-MN-7), Mayor of South St. Paul Jimmy Francis and State Reps. Jon Koznick (R), Emma Greenman (D) and Samantha Sencer-Mura (D).

Experience and exploration: Students delved deep into immersive activities, from solving manufacturing-related puzzles in the Creators Wanted mobile experience to virtually navigating a locomotive through Union Pacific’s simulators. Equally captivating was the sight of the actual railroad track, which was complemented by insightful career anecdotes from Union Pacific professionals.

- Eighty-seven percent of students surveyed reported a significantly improved view of modern manufacturing careers after completing the immersive experience.

Live Q&A sessions: The stop also offered structured opportunities for students to learn about manufacturing organizations’ support for the next generation of talent, along with the importance of mentorship and personal development in shaping successful careers.

- The first session, featuring two Union Pacific senior managers—Amy Bang, Sr. manager of diversity and inclusion, and Ken Kuwamura, Jr., manager of talent acquisition—and Saint Paul College instructors, zeroed in on the crucial roles of mentorship, diversity and passion in career selection.

- The second session, with Jake Yernberg, automotive instructor, Saint Paul College; Caitlin Bundy, manager of corporate sustainability, Union Pacific; and Preeti Subramanian, senior product manager, Trane Technologies, accentuated the pivotal role of manufacturing in tackling global challenges. Panelists pointed out the advantages of the manufacturing sector, citing competitive pay and the sector’s potential in addressing global issues, such as sustainability and climate change.

Interactive Learning: Everfi®, Ecolab and Schwan’s joined Union Pacific in bringing in representatives to give students career advice—and offer activities to spark their curiosity.

- Everfi® showcased a new digital education program, “Future Creators,” co-developed with the MI and Union Pacific, to give middle and high school students a peek into STEM careers.

- Saint Paul College also took students on a tour of its robust Trades and Technical Education program.

Beyond the Tour: The Twin Cities event is a part of Union Pacific’s overarching “Careers on Track” initiative, which aims to inspire more women and youth to pursue modern industrial careers, and the Creators Wanted campaign’s sustained drive to enhance perceptions of manufacturing careers in the United States and empower more people to create the future.

The last word: “I want all of you out here, the students, to have an opportunity to go out there and win and compete and further your careers and do well in life,” said Rocker, echoing a theme the Creators Wanted Tour has promoted since its inception: manufacturers and manufacturing care about students and their future.

Next up: The pioneering Creators Wanted Tour concludes next month, Oct. 17–21, at the Circleville Pumpkin Show in Circleville, Ohio.

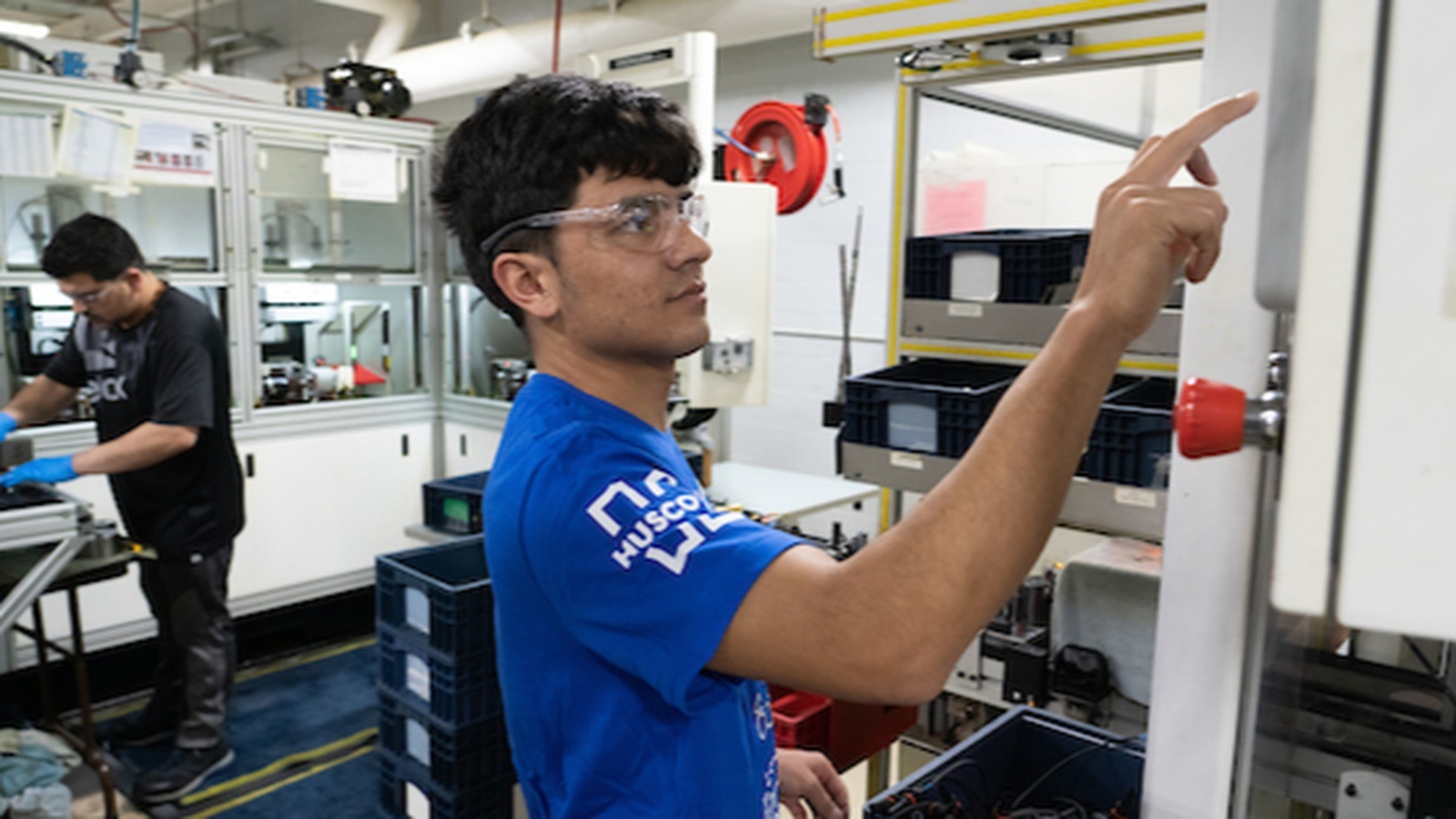

Husco Cracks the Employee-Retention Code

For Husco—a family-owned manufacturer of hydraulic and electro-mechanical control systems—building a strong, cohesive culture is the key to retaining talent.

The Waukesha, Wisconsin, company is among the many manufacturers that find retention to be a top business challenge, as the NAM’s quarterly Manufacturers’ Outlook Survey shows. So how do they create this cohesion?

It all starts at the top: Angela Stemo, vice president of global human capital at Husco, says the company has always prioritized trust and communication between employees and their managers.

- “Our retention has grown and strengthened because of the emphasis we place on our leaders having strong relationships with their employees—get to know who they are, find out what their interests are,” said Stemo.

- The company also lays the groundwork for strong bonds between coworkers, which often flourish outside of work as well. “Once they feel connected to people within the organization, they’re going to want to stay,” explained Stemo. “They’ve built friendships, they’ve built connections, and they feel really tied to the organizational culture.”

How they do it: Husco conducts employee engagement surveys once a year and holds occasional in-person focus group discussions to get feedback from employees.

- “As our organization becomes more diverse, we are offering surveys in more languages,” said Stemo. “We have a large Afghan population on our shop floor as well as many Burmese workers, so we’ve had our surveys translated into various languages for all employees to participate.”

- “For us, we really try to listen to what people say and what their suggestions are,” said Stemo. “If it’s something feasible and we can implement it, we try to figure out how to do so.”

Career development and advancement: Stemo noted that workers have consistently mentioned career development and advancement in the focus groups and surveys. The company has responded by expanding its offerings:

- Husco offers its workers 100% tuition reimbursement—whether for an associate’s, bachelor’s or master’s degree—and fully funded internal and external training.

- The company also offers a “scholars program” that helps recent high school graduates complete a bachelor’s degree in mechanical engineering while working at Husco. Scholars receive full-time pay and benefits along with 100% tuition support.

- “Husco emphasizes and truly supports lifelong, continuous learning,” said Stemo.

Internal programs: Within the company, Husco offers career development programs that feature rotations through different departments, such as quality, manufacturing and design. These rotations prepare workers for leadership positions, usually in engineering or manufacturing, said Stemo.

- Husco provides the opportunity for employees to pursue external certifications in Six Sigma (green, yellow or black) and project management, as well as attend classes in negotiation, presentation and communication through a third party or university/college. If an employee has the desire and completes the appropriate request forms, the company approves it, said Stemo.

Patent awards: Husco also provides a monetary reward for ideas that contribute to new products, processes or anything else that might be patented.

- “There is a staff engineer within each division who partners with various legal teams to apply for a patent award,” explained Stemo. “We recognize the award with a plaque and a patent award bonus.”

Other perks and support: Husco offers employees the flexibility of working one day a week from home and provides free health risk assessments, flu shots and on-site medical consulting. Through a corporate membership, the company also provides employees with day passes to visit the local zoo or museum for free.

Philanthropy: Philanthropy is central to Husco’s culture, and the company encourages its employees to get involved and help their communities. Husco supports employees’ philanthropic efforts through local outreach programs and volunteer opportunities.

- Husco donates 10% of its profits to charitable organizations, putting a special emphasis on those that support K-12 education. The company also donates to colleges and universities, while providing scholarships for exceptional local students and the children of Husco employees.

- “We match dollar to dollar employee donations to hundreds of different organizations,” noted Stemo. “Our philanthropic efforts are a big part of our culture and what makes employees ‘sticky.’”

The last word: Stemo shared some advice for companies struggling with workforce retention: there’s no substitute for good leaders.

- “People leave bosses,” she said. “It may not be the final reason why someone leaves a company, but a lot of times, that’s the beginning of why someone starts looking for a job elsewhere or takes that recruiter call.”

Go deeper: The Manufacturing Institute—the NAM’s 501(c)3 workforce development and education affiliate—has many resources to help employers retain and develop their teams.

- Start with this study on boosting retention and employee engagement, and register for an upcoming webinar on company culture.

- Interested in labor data and key workforce insights? Sign up for the MI’s new monthly publication, Workforce in Focus.

- For more on the latest trends and best practices in workforce development, sign up for the MI’s Workforce Summit on Oct. 16–18 in Atlanta. Click here for more information and to register.

Manufacturers: Impact of Strike Will Echo Far Beyond Detroit

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons released the following statement on the United Auto Workers’ announcement to start a “Stand Up” strike:

“The impact of this strike will echo far beyond the city of Detroit as multiple economic analyses have demonstrated. The small and medium-sized manufacturers across the country that make up the automotive sector’s integrated supply chain will feel the brunt of this work stoppage, whether they are a union shop or not.

“American families are already feeling economic pressures from near-record high inflation and this will only inflict more pain. We urge a swift resolution to end this strike and avoid further undermining the strength of our industry and harming our broader economy.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.91 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Overregulation and Workforce Challenges Weigh Heavily on Manufacturing Sector

Optimism Sinks to Pandemic Lows in Q3 Outlook Survey

Washington, D.C. – The National Association of Manufacturers released its Manufacturers’ Outlook Survey for the third quarter of 2023, which registered the lowest level of optimism among NAM members (65.1%) since Q2 2020, as the sector continues to confront a tight labor market, unbalanced federal regulations and critical policy debates in Congress.

“Manufacturers continue to be challenged in today’s economy, but what this survey makes clear is that unbalanced federal regulations are harming families and communities, with nearly two out of three manufacturers reporting that the regulatory burden is preventing them from hiring more workers or increasing pay and benefits,” said NAM President and CEO Jay Timmons. “Congress and the administration can help correct this trend by restoring sensible regulations, enacting further permitting reforms, taking action to keep our tax code competitive and other bipartisan steps to strengthen manufacturing in America and build on the progress we achieved with tax reform, the Bipartisan Infrastructure Law, the CHIPS and Science Act and more.”

Key Survey Findings:

- Only 65.1% of respondents felt positive in their company’s outlook, edging down from 67.0% in the second quarter. It was the fourth straight reading below the historical average (74.9%).

- Concern about an unfavorable business climate was the highest in six years (Q2 2017).

- The survey found that 69.1% of small manufacturers, and 63.2% of all respondents, would hire more workers or increase compensation if the regulatory burden decreased.

- More than 70% of manufacturers would purchase more capital equipment if the regulatory burden on manufacturers decreased, with 48.6% increasing compensation, 48.6% hiring more workers, 42.5% expanding their U.S. facilities and 38.4% investing in research.

- The top challenges facing manufacturers include attracting and retaining a quality workforce (72.1%), weaker domestic economy (60.7%), rising health care/insurance costs (60.1%), unfavorable business climate (56.7%), increased raw material costs (45.5%) and supply chain challenges (37.8%).

You can learn more at the NAM’s online regulatory action center here.

The NAM releases these results to the public each quarter. Further information on the survey is available here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.91 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

How Manufacturers Can Tap into a Large, Talented Workforce

Discipline, reliability, a team-player mindset, leadership—manufacturers are looking for all these qualities in the talent they recruit. What if companies could tap into a population not only equipped with these skills but experienced in using them in high-stakes situations?

Well, the Manufacturing Institute—the workforce development and education affiliate of the NAM—has good news, if you haven’t heard it already: this population exists, and it’s military talent. Transitioning service members, veterans, National Guard members, reservists and military spouses have a wealth of skills and experience that translate easily into a manufacturing context.

So how can manufacturers reach these workers and make the best use of them? The MI recently convened both military and manufacturing leaders in Fayetteville, North Carolina, for its third Workforce Solution Series event, where they answered this question and offered a range of useful advice. Here are some of the highlights.

Generally speaking: Major General Eugene J. LeBoeuf, Deputy Commanding General, U.S. Army Reserve Command, highlighted the talents and skillsets that Army reservists can offer the manufacturing industry, including agility, a can-do attitude and a thorough grounding in engineering, logistics and mechatronics.

- With nearly 190,000 soldiers, the Army Reserve comprises much of the readiness force of the U.S. Army. Many of these reservists are underemployed or unemployed, which means they represent an opportunity for manufacturers.

- Manufacturers interested in hiring from this labor pool can partner with the Private Public Partnership Office, which connects companies with reservists at no cost.

Reaching military talent: Several panelists emphasized the importance of developing recruitment processes that encourage military talent to apply and interview for manufacturing jobs.

- “Make sure that the requirements you’re listing in your position descriptions are actually required. Do you really need someone to have a master’s degree to get the job done?” asked Rob Patton, vice president of Fayetteville Cumberland Economic Development Corporation.

- As a recently transitioned service member, James Goppert, HR business partner at WestRock, explained some of the challenges that military talent may face when entering the workforce. “Having to explain military skills and certifications to a civilian in an interview was strange. It would have been helpful to have someone on the other side who understood my experiences.”

Open to all possibilities: Jennifer Goodman, senior manager of talent initiatives at Coca-Cola Consolidated, drew on her experiences as a military spouse. “Military spouses are 92% women and have a 22% unemployment rate. That’s a huge labor pool that’s going underemployed or unemployed.”

- While relocation is often a concern for companies, Goodman points out that it does not have to be a disadvantage. “Think of manufacturers who have locations across the country. Maybe you can start a military spouse at one location and then move them to another. Or, if they’ve proven themselves after a few years, you could transition them to remote work.”

- “The benefits don’t stop with the one military spouse you hire,” she added. “We’re a very loyal community with great word of mouth and a larger referral network.”

The last word: “Don’t underestimate the value of an event like this Solution Series can have. You can take the information, energy and passion that you get from meeting with people who have the same goal of building a stronger economy and use it to power you forward,” said Nathan Huret, economic development director for Catawba County.

Learn more: To get started—or continue—with hiring military talent, check out the extensive resources of the MI’s Heroes MAKE America initiative, which prepares prospective military workers for new and rewarding careers in manufacturing.

STEP Ahead Awards Honor Women in Manufacturing

The Manufacturing Institute’s 10th annual STEP Ahead Awards took place in Washington, D.C., last week, honoring some of the most impressive and inspiring women in the manufacturing industry today. The Awards are part of the STEP Ahead program, which is designed to help advance women’s achievements in the fields of science, technology, engineering and production.

- The event highlighted the 2022 STEP Ahead Honorees (100 women who are leaders in manufacturing) and the 2022 STEP Ahead Emerging Leaders (30 women under 30 years old who have already had a significant impact on the industry).

The awards ceremony took place on Thursday night, with hundreds of guests in attendance at the National Building Museum and hundreds more viewing the ceremony online. The program featured:

- 2022 STEP Chair and former 3M Senior Vice President Denise Rutherford;

- 2022 STEP Vice Chair and Cornerstone Building Brands President and CEO Rose Lee;

- MI President Carolyn Lee;

- MI Vice President of Strategic Engagement and Inclusion AJ Jorgenson; and

- NAM President and CEO and MI Board Chair Jay Timmons.

Sponsors included an all-star roster of manufacturers, including Arconic Foundation, BASF Corporation, Cornerstone Building Brands, PTC, Trane Technologies, ABB, Molson Coors, Novelis, Rockwell Automation, SABIC, Sherwin-Williams and Toyota.

What they said: Carolyn Lee lauded the Honorees and spoke about the importance of closing the skills gap by bringing more women into the manufacturing industry.

- “My hope is that 10 years down the line, when we meet here for the 20th anniversary of these awards, the young women we will honor won’t have even heard of the glass ceiling, because it’ll be ancient history,” said Lee.

- “And that will be thanks to the support system, the mentorship and the sterling examples set by the women in this room and the support from our allies.”

Rutherford spoke about leaders’ opportunities to work together to make important progress.

- “Throughout my career, I’ve learned that being a great leader, as an individual or as a company, means that we don’t go it alone,” said Rutherford. “True change only happens when we work together as trusted allies, advocates and sponsors.”

Rose Lee laid out the qualities that all the Honorees showed and highlighted their shared successes.

- “The STEP Ahead Awards recognize women in science, technology, engineering and production who exemplify leadership within their companies and within their communities,” said Lee. “Tonight is their night to celebrate their accomplishments.”

Timmons praised the STEP Honorees and called on allies to continue supporting women in the manufacturing industry.

- “Your achievements, your success and your dedication are showing women what’s possible in manufacturing,” he said. “If you can see it, you know you can be it.”

35×30: Carolyn Lee and Jorgenson spoke about the 35×30 initiative—a program designed to close the skills and talent gap in manufacturing by adding half a million women workers to the industry, increasing women’s representation in manufacturing from 29% today to 35% by 2030.

- The campaign will train more than 1,000 women mentors, build new tools and resources and work with manufacturing leaders to deploy proven strategies to attract and retain female talent.

- It will also support young women throughout their education by offering best-in-class leadership development programming and creating a STEP alumnae-funded scholarship.

- “Tonight, we are done with waiting for other leaders to ‘change things,’ to make society better, more equitable,” said Jorgenson. “We are the leaders. So, tonight, we ask you to join us, to lead.”

New commitments: To help this new initiative along its way, Arconic Foundation President Ryan Kish and Ketchie CEO Courtney Silver stood up during the ceremony to pledge new financial commitments to the program.

The last word: The gala featured a stellar musical performance by award-winning singer–songwriter Rachel Platten, which left not a dry eye in the house. Inspired by the women of STEP, she surprised the audience by singing a new song she’d written for her daughters. It captures what the women leaders of today want to tell the girls who will someday be their heirs:

Girls, you were born to run. To reach the stars and chase the sun.

Girls, you’re wild and free. The wind is at your back, the world is at your feet.

Parts Life Helps Workers Achieve the American Dream

Attracting and retaining a quality workforce has long been a top business challenge for manufacturers. The Parts Life Inc. family of companies is no different—but its variety of workforce strategies have led to considerable hiring success.

The Moorestown, New Jersey–based manufacturing group—which consists of engineering firm Parts Life, armament support manufacturer DeVal Lifecycle Support and electrical manufacturer LC Engineers—offers a number of inducements for new and existing workers, President and CEO Sam Thevanayagam explained. Together, they are helping the companies, and their workers, thrive.

The plan: “We create an environment where [people] can achieve their God-given potential,” Thevanayagam told us.

- After being inspired by several books—David Docusen’s “Neighborliness” and Hernando De Soto’s “The Mystery of Capital” among them—Thevanayagam sought to provide workers with a range of benefits, some of them unusual for an employer to offer.

- “In ‘Neighborliness,’ [Docusen] realized people need education, a job, health care and housing to be successful and build community,” Thevanayagam said. “So we are making sure we are offering these things to our people.”

- For example, Parts Life recently devised a financial program called Help U Buy, which helps workers buy their first homes.

Helping the whole employee: Parts Life offers its employees a variety of educational opportunities to help them advance at the company and better their lives.

- Approximately 40% of the workforce at DeVal Lifecycle Support is made of immigrants to the U.S., according to Thevanayagam.

- To help employees learn the language, the Parts Life companies offer no-cost formal English courses with a trained Teaching English as a Second Language instructor. “It’s helped them not just at work, but in being better neighbors, parents and citizens, too,” Thevanayagam

- The businesses also offer free basic financial management classes for workers.

Upskilling: Several years ago, when a nationwide shortage of trained machinists began to impede the companies’ operations, Thevanayagam devised a fix. Parts Life would “create” its own machinists.

- “As difficult as it is to find a trained machinist, it’s even harder to find teachers” for machining, Thevanayagam said. Once Parts Life found and hired a machinist instructor, the company had him begin training other employees.

- “Now he’s working with about 10 of our machinists—upskilling them, teaching them everything” they need to know, Thevanayagam said. “He’s sort of like a pitching coach, working with them on their technique and speed. That’s the model we’re using. … It really increases employee engagement and retention.”

Talent in the community: The Parts Life family of companies is also building relationships with local schools in an effort to find potential hires.

- These include partnerships with technical high schools that offer welding and machining training and partnerships with local colleges and universities to source engineering and business talent.

- “I look at [the partnerships] as building an entire ecosystem,” Thevanayagam said. “These are ways to be able to recruit and retain good people.”

Veterans: Lastly, Parts Life has had success in hiring from another pool: veterans. One of the reasons? It is willing to provide needed accommodations.

One recent veteran hire, a former U.S. Marine, had post-traumatic stress disorder and a substance-abuse problem when he was brought on board and “we were able to … get him counseling and get him a support system through veterans organizations,” Thevanayagam said.

- “We try to be veteran-ready,” said Thevanayagam, adding that veterans now account for about 3% to 5% of Parts Life companies’ workforces. “These are people who have sacrificed for our country—and I want to make sure we are an environment where they can achieve.”

The last word: “The fact that we’re able to create meaningful work for people so they have the ability to … become part of the American dream—it’s a big part of who we are,” said Thevanayagam.

Read more: As the 501(c)3 nonprofit workforce development and education affiliate of the National Association of Manufacturers, the Manufacturing Institute is a trusted adviser to manufacturers, equipping them with solutions to address the toughest workforce issues. Visit the MI’s site for workforce solutions insights and resources.

Creators Wanted Makes an Impact at SkillsUSA

The Creators Wanted tour landed in Atlanta last week for the SkillsUSA National Leadership and Skills Conference—the largest gathering of the America’s future skills workforce.

Over the course of the three-day program, the tour, an initiative of the NAM and the Manufacturing Institute, helped change attitudes and challenge misconceptions about manufacturing, opening up a new world for some of the country’s most talented rising workers.

By the numbers: The tour’s SkillsUSA stop, sponsored by Honda, Snap-on, FactoryFix and Union Pacific, helped share the story of modern manufacturing with many of the brightest career mentors and technical education students in the United States.

- 15,000 people attended the event, including many career and technical education students, educators and parents.

- More than 1,500 people took part in the Creators Wanted immersive experience at SkillsUSA.

- More than 120,000 students and career mentors signed up to learn more about modern manufacturing careers during the tour stop in Georgia.

More participants: Other leading manufacturers were also in attendance, engaging students with information about careers in manufacturing. A few of the participants included Caterpillar, John Deere/Korematsu, Volvo NA Group, Vermeer Corp., Toyota, Cummins, Penske and 3M.

A special guest: Snap-on Chairman and CEO Nick Pinchuk dedicated a full day to inspiring students and educators. The NAM executive committee member and Manufacturing Institute board member emphasized the “Creators Wanted” mantra in order to remind participants that manufacturers aren’t just recruiting workers—they’re inspiring and empowering creators.

Local coverage: The visit made waves in Georgia, where it was covered on Fox 5’s Good Day Atlanta:

- “A huge turnout down here,” said Fox 5’s Paul Milliken, who had multiple live hits at the Creators Wanted immersive experience. “These students are so talented, so incredible … the future of America’s skilled workforce.”

- “This conference—it’s just a really incredible opportunity for these future workforce leaders to come together, meet each other, network and compete.”

WATCH: @GoodDayAtlanta's @PaulFromFox5 reports on #CreatorsWanted traveling to @GWCC_ATL for @SkillsUSA #NLSC23. Check out how we are working to inspire students to consider rewarding careers in modern manufacturing. https://t.co/0GAlhxDmTb pic.twitter.com/BFJeKyXS9G

— The NAM (@ShopFloorNAM) June 20, 2023

Overheard at the event: Plenty of participants shared their excitement, emphasizing opportunities to connect with employers, learn about new skills and find paths to future careers.

- “These are viable careers. They are jobs that you can make quite a bit of money right from the beginning, and at the same time you’re learning core skills that you can carry on for the rest of your life.”

- “We’ve got tons of jobs out there across the U.S. Everybody is looking for talented individuals.”

- “You can explore … different careers that you want to do, [to] help you become a more successful adult in the future.”

The big picture: Over the course of the Creators Wanted Tour, which launched a year and eight months ago:

- 4 million students and career mentors have signed up online to learn more about modern manufacturing careers.

- Over 10,000 students and more than 3,000 career mentors have participated in our immersive experience, with 84% reporting a significantly improved view of modern manufacturing careers.

- The tour has received $5.35 million in positive earned media and 150 million digital impressions.

Making an impact: “Interacting with the students, educators and caregivers, we could truly feel the impact we’re making,” said Chrys Kefalas, managing vice president of brand strategy at the NAM. “This isn’t just about changing minds—we’re creating dreams and altering life trajectories.”

What’s next: The tour keeps on rolling this fall to Minneapolis and St. Paul, Minnesota, and Circleville, Ohio. You can also keep an eye out for new online resources that are coming out this summer, or browse the more than 330,000 open manufacturing jobs and 150,000 training programs listed online.

“Listen and Act”: Bishop-Wisecarver Shares Retention Secrets

Keeping her employees happy and engaged is something Pamela Kan, president and owner of Bishop-Wisecarver, takes seriously.

And for good reason. Workforce retention is a pain point for many manufacturers and consistently cited, along with recruitment, as a top business challenge in the NAM’s Manufacturers’ Outlook Survey.

For Kan, meeting this challenge starts with getting her employees’ input—what’s on their minds, their career aspirations and the ways they think the company can improve. Then she acts on it.

Garnering feedback: To assess engagement, Bishop-Wisecarver surveys its employees and calculates an employee net promotor score, which is an internal measurement of employee satisfaction. Kan, the executive director of culture and people and department heads then discuss the areas that need improvement.

- “We share with employees where we have friction points or where things need to change,” Kan said. “We make that very visible. We then start checking these things off the list.”

The company also offers employees many different opportunities to share what’s on their minds, through informal check-ins, team huddles, employee lunches and skip-level meetings.

- “Every single one of these times we are asking for feedback,” Kan emphasized. “We document it and follow up on it, because whenever you ask for feedback and you don’t then respond with changes or next-level discussions, you break the trust with your employees that you care about them.”

- “I reach out to new employees at the 60-day mark to see how it’s going,” she continued. “One actually reached out and said, ‘yeah, we need to talk.’ It was all positive. Some things he didn’t quite understand, being new [to the company], and it showed me some gaps in our onboarding process.”

Conducting reviews: Instead of formal reviews, Kan says Bishop-Wisecarver has instituted quarterly check-ins, with the conversations often centering around career advancement.

- “We’ve tried to create a career ladder that’s not just vertical, but allows for offramps where employees can explore different channels of the company,” said Kan.

- “If somebody starts as an application engineer, that doesn’t mean they have to stay in engineering. They might want to go and try a position in sales, project management or marketing. We leave the door open.”

Other strategies: Kan has also implemented several other workplace practices to keep employees engaged.

- Recognizing employees: Through a program called “Bishop-Wisecarver Bucks,” employees receive a bank of bucks once a month that they can use to recognize others who have lived up to one of the company’s core values: preserve the family culture, deliver a signature experience, embrace a pioneering spirit and the need for speed. The company has an online portal where those receiving the bucks can purchase company merchandise, gift cards or tickets to events.

- Inspiring the next generation: Based on feedback from her employees, Bishop-Wisecarver partners with multiple nonprofits that support students in their local community. One of these is FIRST Robotics, which inspires young people to be science and technology leaders and innovators, as well as well-rounded contributors to society, by engaging them in mentor-based research and robotics programs.

- Reimagining the workspace: After polling her employees, Kan redesigned an entire building to reflect the workstyles and needs of her team. For example, the second floor of the building is now a large training space, where tables, chairs and white boards have wheels for easy configuration for company-wide meetings to multiple small groups. To break down the silos of separate lunchrooms, she created Wisecarver Way Café, complete with a pool table and ping-pong table. The company also has a space for employees to do yoga, allows them to bring their dogs to work and offers gym memberships.

- Offering support: Bishop-Wisecarver also has a program called Life Guides, which connects employees undergoing hardships with peer mentors who have been through similar difficulties, such as caring for an elderly parent or coping with a death in the family.

The last word: “Don’t ask your team for feedback and then do nothing with it,” Kan reinforced. “That’s what creates disengaged team members. Sometimes we don’t get it right, but at least we’ve tried.”

The Manufacturing Institute has many initiatives to help employers retain and develop their teams. For a deeper dive, check out this study by the MI on improving retention and employee engagement. The MI will also explore retention challenges and solutions at its Workforce Summit in Atlanta on Oct. 16–18. Click here for more information.